[ad_1]

The SEMA exhibition, a prominent showcase for aftermarket car components that coincides with Halloween in Las Vegas, carries a reputation akin to the city itself. It’s often viewed as more about style than substance, featuring flashy but often impractical creations fueled by gimmicky products. Having recently attended SEMA in person, I’m delighted to report that the event surpassed my expectations. These videos chronicling the transformation of Toyota’s FJ Bruiser demonstrate the high levels of ingenuity and intricate craftsmanship on display.

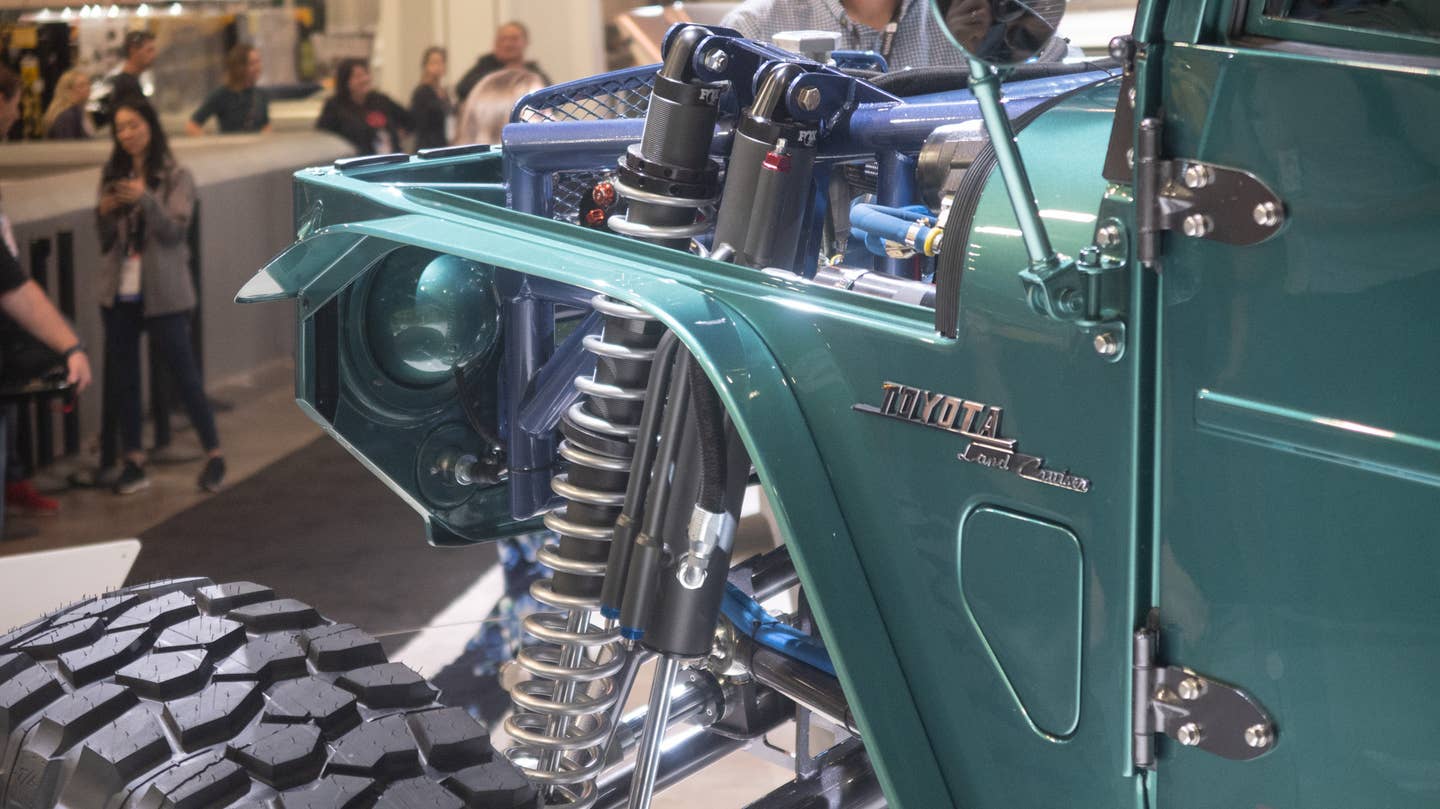

Enthusiasts familiar with Ultra4 racing and The King Of The Hammers will quickly recognize the key features of this project: a powerful engine, oversized tires, and four-wheel drive—a hallmark of modern desert racing. In contrast to traditional Baja-style vehicles built for speed and stability with rear-wheel drive and slightly smaller tires, Ultra4-style rigs are characterized by their tall and sturdy build, geared more towards navigating rocky terrains.

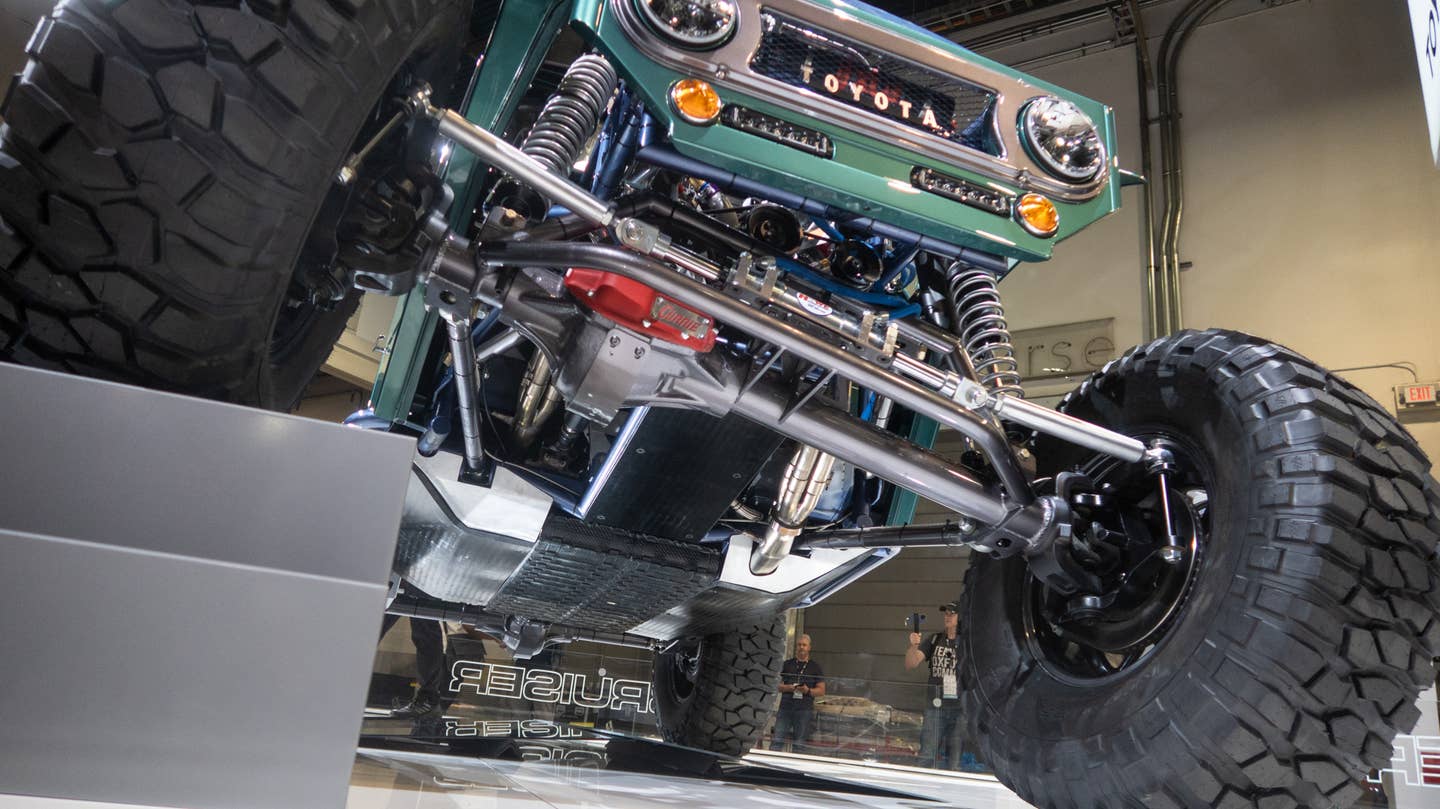

This style of racing is intriguing, and while Toyota has not suggested that the FJ Bruiser concept will enter competitive motorsports, it’s evident that Ultra4 racing served as a major source of inspiration for this build. More than just fitting 42-inch BF Goodrich Krawler T/A KX tires and a potent 358 cubic-inch V8 engine, the project draws from the demands of events like The King Of The Hammers, where vehicles must ascend steep rock faces relying on torque and large wheels, and often necessitate winching and extrication from challenging positions. Moreover, self-sufficiency is crucial as competitors are not always willing to lend a helping hand.

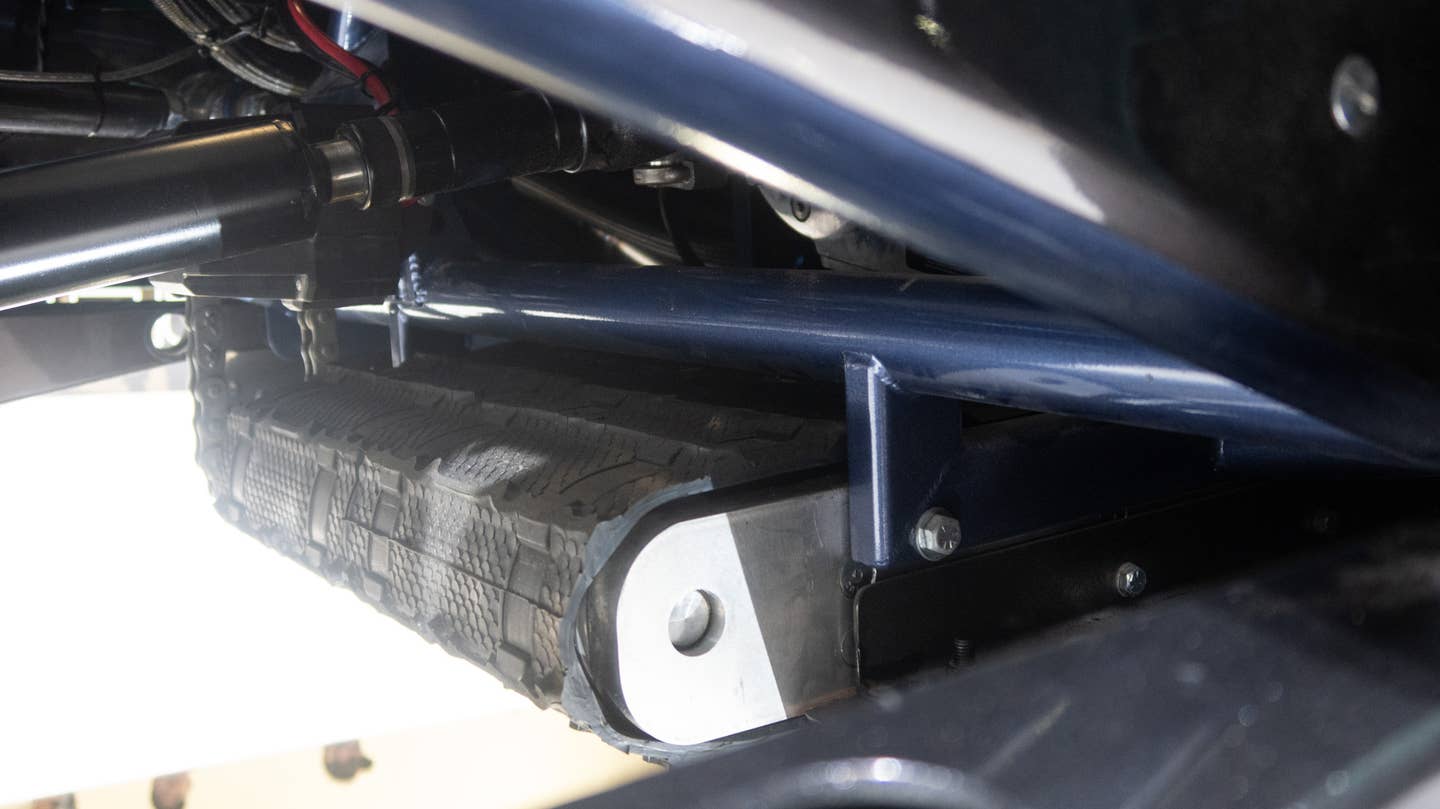

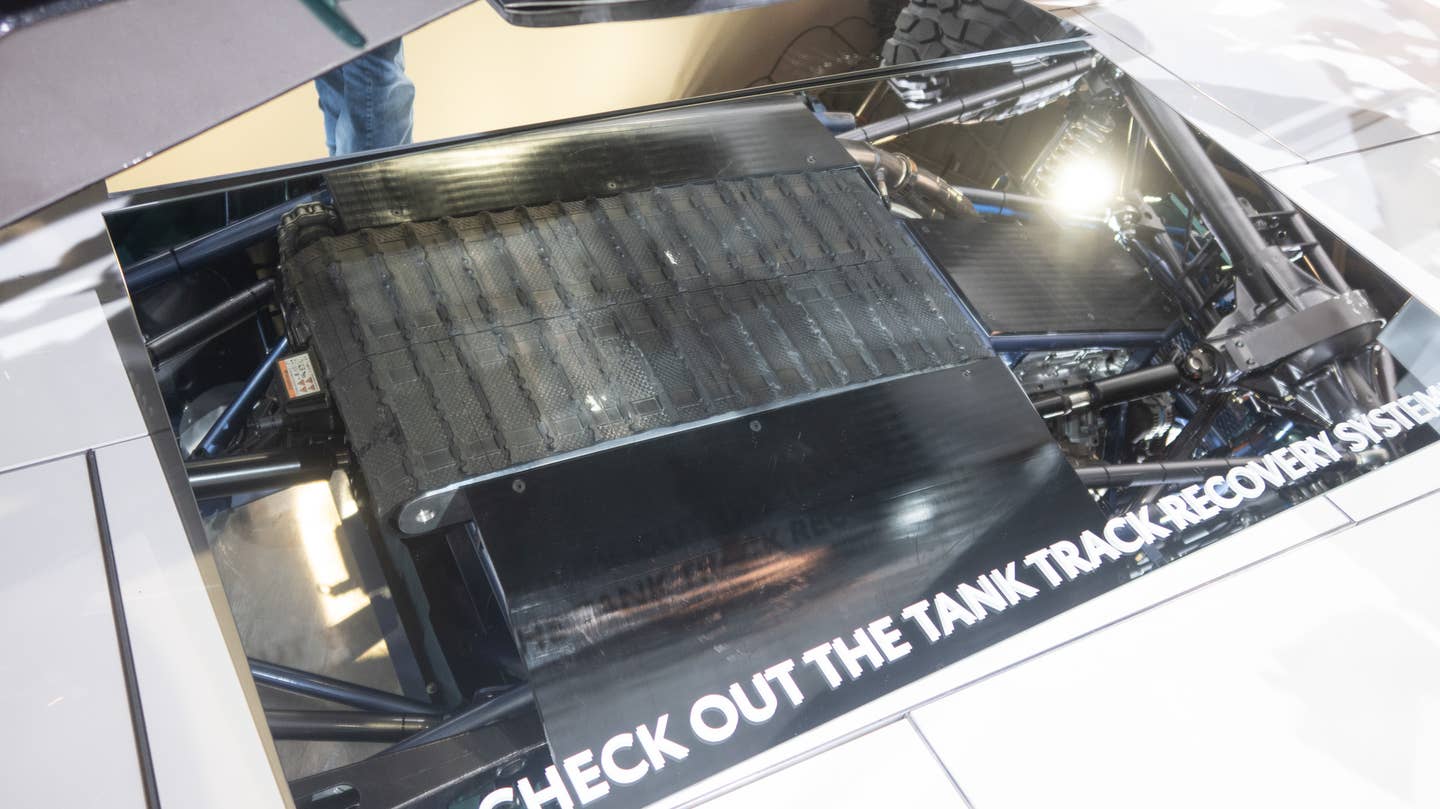

Toyota’s Motorsports Garage Team Manager, Marty Schwerter, and Lead Fabricator, Brad Vetter, devised an innovative self-rescue feature for this vehicle: a tank-like tread beneath its underside, designed to help propel the truck off obstacles or surfaces where it could potentially become stuck.

While the effectiveness of this solution in challenging environments like Johnson Valley, where Ultra4 cars are tested, remains uncertain without real-world trials, the concept and initial execution with the FJ Bruiser are undeniably impressive and entertaining. The accompanying clips show the tread in action, confirming its functionality—it utilizes a Camso track similar to those found on snowmobiles. Toyota deserves credit for investing in this creative endeavor, showcasing the ingenuity that skilled engineers can achieve with the right tools, time, and resources.

I’ll share my photo gallery from the event floor later on, but first, take a look at the videos detailing the genesis of the FJ Bruiser.

The initial clip showcases the original Toyota truck used as the base for the project:

Next, the team discusses the fabrication of the frame and the unique tank tread (referred to amusingly as a “conveyor belt” rather than a “tank tread”):

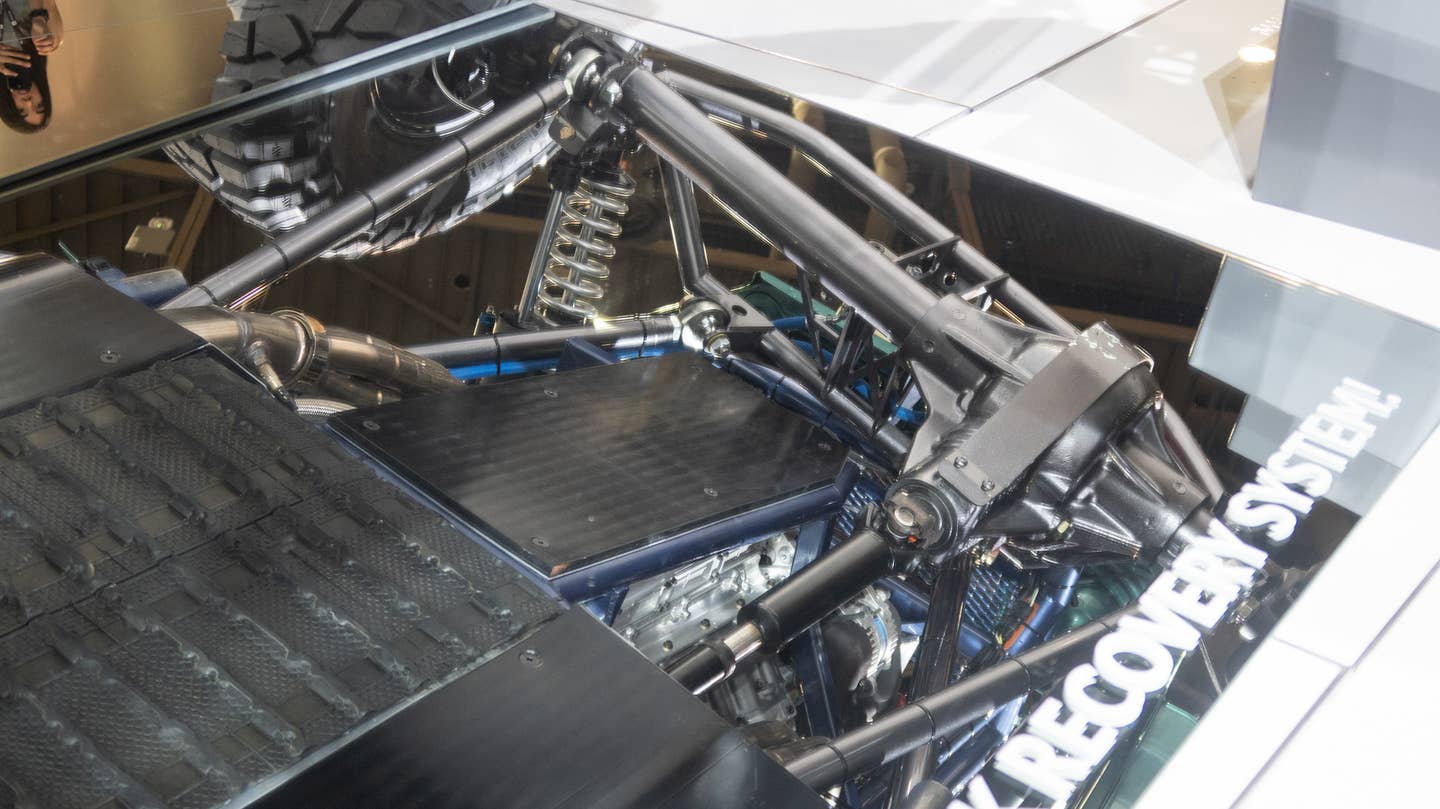

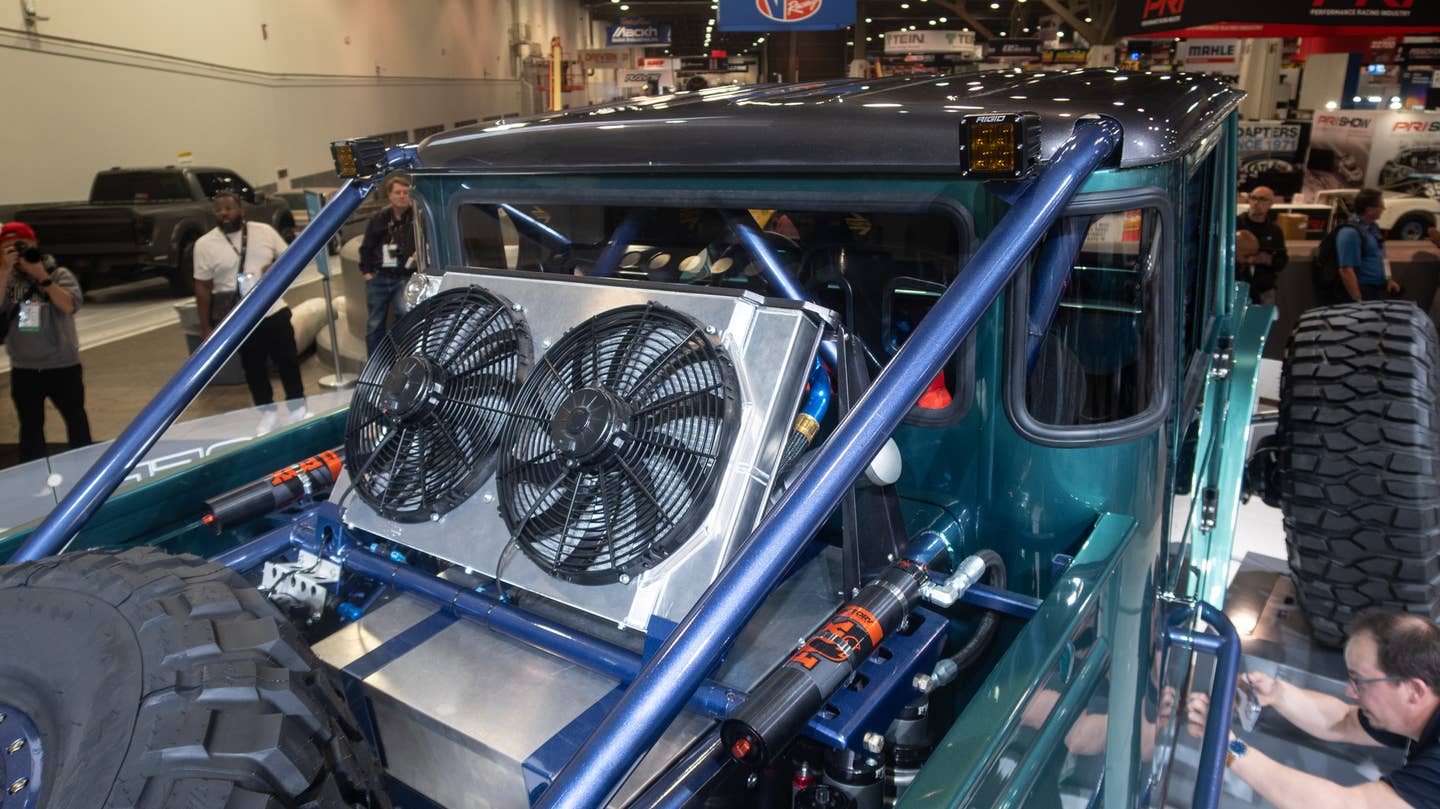

The essential activity shown in the third clip is the installation of necessary wiring and plumbing vital for powering the truck.

The last stages of the FJ Bruiser creation process are discussed by the builders, with work being completed continuously for “36 days straight … with 12-hour shifts.” Vetter raises an interesting point: “We are constructing a vehicle entirely from scratch. None of the components such as the brake pedal assembly, steering wheel, or suspension are pre-assembled. Every single piece needs to be meticulously handled or installed to make a fully operational vehicle.”

A noticeable absence in this footage is the sound of the Bruiser’s high-powered 725-horsepower NASCAR Cup Car engine resonating from its MagnaFlow exhaust. Fortunately, The Drive‘s Instagram has got you covered:

Many Instagram users believe the sound in the video is artificial (why would we do that?) I can confirm the audio is authentic as I recorded it with my personal iPhone! The stationary “flaps” on the air intake are purely decorative and do not move.

Now that you’ve enjoyed the audio, here are some stunning visuals of the FJ Brusier for you to admire:

Finally, if you require a laugh—scroll to the lower part of Toyota’s press release concerning this matter, where it mentions:

“Vehicle mentioned is a unique project prototype vehicle, altered with components and/or accessories not offered by Toyota that could nullify the vehicle’s guarantee, might adversely affect vehicle efficiency and safety, and might not meet legal street requirements.”

Understood, folks? If you’re planning to submit a guarantee claim for your 1966 Toyota FJ45, better ensure it doesn’t contain a NASCAR engine.

[ad_2]