Repeatedly we have emphasized the necessity of a 3D printer in every workshop. If our suggestion doesn’t convince you, just reflect on The Great Ford Maverick 3D Print-Off where Peter Holderith and myself crafted some impressive enhancements for Ford’s most budget-friendly pickup truck. In that scenario, Ford was cooperative by releasing the blueprints for the truck’s Ford Integrated Tether System (FITS); however, other car manufacturers are not as forthcoming.

To address this dilemma, DIYers have turned to reverse-engineering their vehicles. Some individuals resort to calipers and contour gauges, while others, who possess more technological prowess, opt for 3D scanning. Surprisingly, commencing your journey in the realm of scanning doesn’t necessitate a hefty sum of money or the latest technology. You can simply acquire a discontinued Xbox Kinect unit to start.

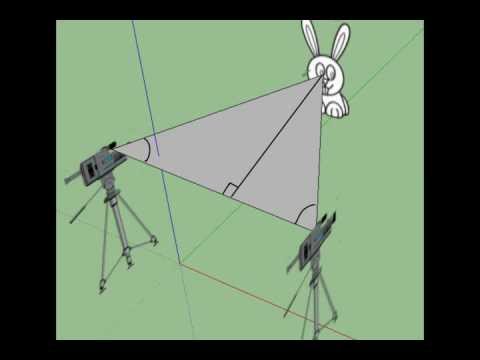

Before delving into the applications of these economical devices, it is crucial to comprehend their functioning and why they offer a superior solution compared to a flat photograph. The primary reason a regular camera is inadequate is that conventional imaging sensors essentially function as monocular devices, lacking inherent depth perception capabilities.

To address this challenge, numerous self-driving taxi companies employ lidar technology. Lidar emits light beams to generate a point cloud, consisting of points along Cartesian coordinates in space that represent a three-dimensional object. In Tesla’s scenario, multiple cameras can create a stereoscopic view of the environment and artificially calculate distances; however, the accuracy of such measurements generated by software compared to purpose-built sensors is often debated.

The Microsoft Kinect sensor’s magic is akin to a hybrid of these two solutions. Although not as robust as a lidar sensor, the Kinect employs light beams (similar to lidar) to determine an object’s distance. It utilizes a dual-camera setup where one camera utilizes a standard vision sensor, while the other captures the infrared beam grid projected by sensors within the Kinect. By mapping the position of the dots projected by the infrared grid, the sensor merges both feeds to form a unified image embedded with depth information.

Now that we have a rough grasp of how the Kinect operates, let’s explore the innovative ways enthusiasts utilize it to fashion their envisioned vehicles.

Both DIYers and constructors predominantly employ these Kinect-generated scans either to reverse-engineer vehicle parts or simplify the modeling process for intricate shapes and contours. For instance, one Mazda Miata owner utilized it to craft new headlight housings, while another individual utilized it forCreate a spoiler for their Audi, brake ducting, toggles, central panels (featuring gauge pods cutaways), substitute door grips, and even complete induction manifolds.

Several other instances can be discovered in a few of my cherished car-oriented three-dimensional imprinting Facebook collections, like “3D Printing Auto and Moto” and “Miata 3D Printing Association.” Nonetheless, there is a particular project I want to highlight that I have presented before; Crucible Coachworks’ Porsche 911 slantnose project.

Ryan Krause, the constructor behind this transformed 996, has been sharing progress reports on social networks for a while. Over time, he has articulated how traditional metal molding techniques can be melded with modern 3D imprinting—and the retro appearance of the Porsche exemplifies how these two techniques can harmonize.

Krause kicked off his three-dimensional imprinting journey with archaic measuring instruments. The modeling became intricate as he had to construct headlamp housings, grilles, and additional personalized components. This was prior to the project gaining hundreds of thousands of followers on TikTok and Instagram, so Krause resorted to purchasing a Kinect, like any cost-conscious three-dimensional printer would.

Let’s explore the basic process of capturing a model and creating a component. Initially, Krause utilized Skanect for capturing a three-dimensional model with the Kinect sensor. Subsequent to the capture, he imported the model into Blender to refine any anomalies, then transferred the simplified model to Fusion 360 where he adjusted the size. After this, it was all about shaping the prototype for his next component.

Nonetheless, not all is perfect when working with the Kinect. With a sizable model, scans can slow or lose tracking. Eventually, he upgraded to a purpose-built yet still economical alternative, the Creality CR-Scan 01. This facilitated more precise scans. These scans were employed to generate prototype turn indicator lenses, ducting, and grills, as well as headlamp housings for his diverse Porsche ventures.

If you’ve been contemplating a new pastime to complement your vehicular obsession, I would once more advocate three-dimensional imprinting. Once you grasp the art of producing your own components, your potential becomes nearly boundless—or at least confined by your expertise and material availability. So, why hesitate? Venture forth and commence printing.

Got a suggestion or inquiry for the writer? Reach out directly: rob@thedrive.com

[ad_2]