[ad_1]

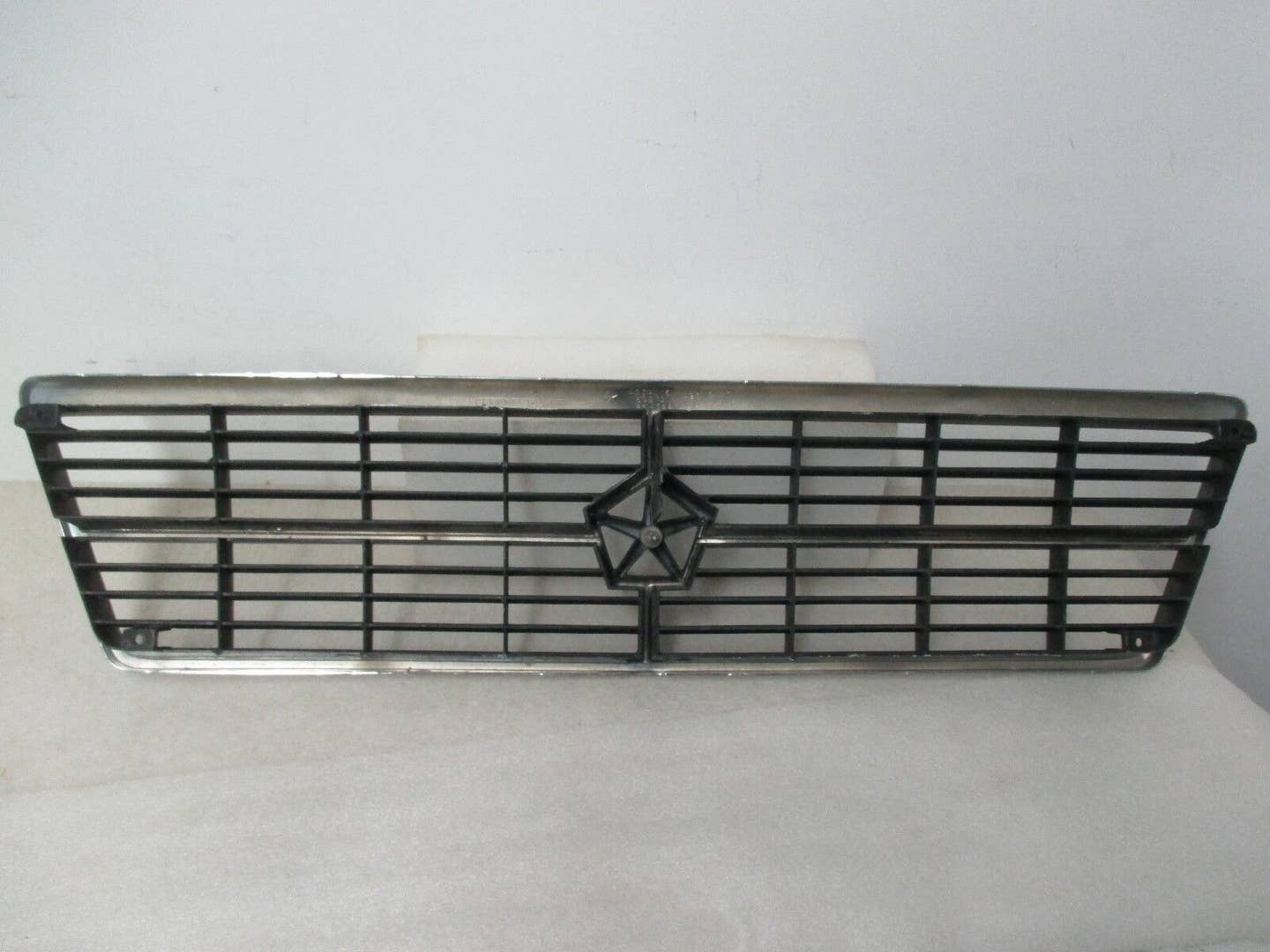

However, it’s worth mentioning that K-cars did not come with solid aluminum grilles; instead, they featured typical plastic grilles with chrome trim. Moreover, sand casting would not have been a common production method for an automotive grille in the 1980s due to the time and labor-intensive nature of the process. Sand casting also would not have been an effective means to create a mold for a plastic part at that time, as it would have resulted in an aluminum grille rather than a negative aluminum mold.

By speculating openly, this piece was likely utilized to produce a prototype grille through a casting method or another molding technique. The resulting piece would then undergo processing and be later used for measurement and development purposes. Having an actual model for measurement would aid in the development and machining of an injection molding die. These dies are typically meticulously crafted from tool steel, enabling them to produce hundreds of thousands of plastic parts swiftly. The use of tool steel is crucial for achieving a fine surface finish and reducing wear after numerous “shots” of molten plastic.

Possibly, someone within the broader engineering community could shed more light on this subject. Nevertheless, it remains a peculiar piece of engineering ephemera that one would not typically expect to encounter outside a Chrysler facility. The fact that it has endured over the years and made its way to a flea market suggests that someone souvenired a little keepsake from the K-Car engineering department. Now, it has transformed into a noteworthy flea market discovery with an intriguing narrative.

Have a tip? Inform the author at: lewin@thedrive.com

[ad_2]