[ad_1]

Researchers at Germany’s Fraunhofer Institute for Machine Tools and Forming Technology IWU, in collaboration with partners from the COOLBat joint research initiative, are pioneering advanced battery enclosures for electric vehicles (EVs).

The COOLBat project aims to create lighter enclosures that minimize power consumption and extend driving range. This is achieved by integrating individual systems, consolidating multiple functions into a compact installation area, and utilizing innovative heat-conductive materials along with bio-based flame-retardant coatings.

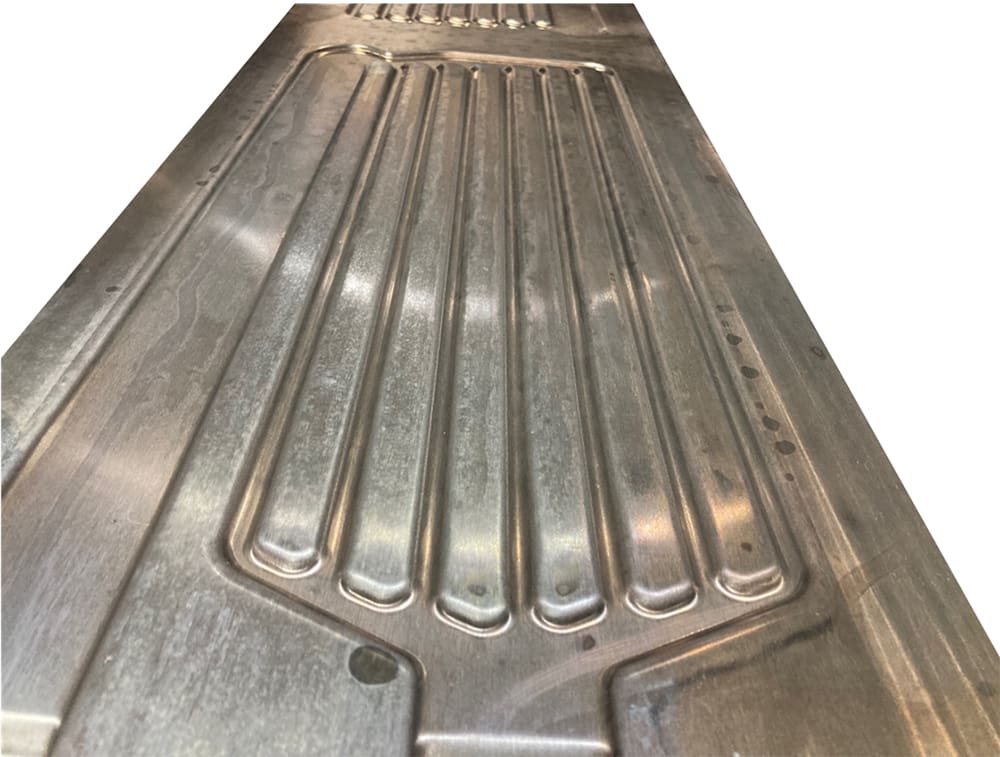

The team is experimenting with consolidating previously separate thermal and mechanical functions within the enclosure. Notably, the cooling unit and underride protection have been combined into a single component—the base plate.

To absorb impact energy during collisions or stone strikes, the base plate incorporates aluminum foam. Additionally, it features phase-change material (PCM), a wax-like substance capable of storing and later releasing thermal energy, which further enhances cooling efficiency.

This innovative design not only shields battery cells from mechanical stress but also from excessive heat. A cooling fluid circulates through channels, maintaining optimal cell temperatures from beneath and alongside, significantly lowering the energy required for cooling and eliminating the need for additional cooling components within the vehicle.

A key project objective is to replace heavy conductive pastes with environmentally friendly heat-conductive materials for connecting battery modules thermally. The researchers are employing a plasma process to metallize reusable open-pored foams, which are subsequently positioned in pad form between the battery and the enclosure.

A novel flame-retardant coating applied to the underside of the enclosure lid prevents fires from igniting due to battery cells overheating. The traditional steel lid has been replaced with a lighter fiber composite version, which reduces weight and allows for potential reuse.

The researchers are utilizing the Mercedes-Benz EQS battery as a reference model and technological showcase.

Looking ahead, the project aims to apply its findings to other sectors that utilize large batteries, including rail transport, aviation, and maritime applications.

“We are focused on creating functionally integrated structures. Tasks that were once managed by various modules within the battery are now being combined into a single component—the base assembly—to minimize installation space and enhance interface efficiency,” explained Rico Schmerler, project manager and scientist in the Battery Systems department at Fraunhofer IWU. “These base plates will safeguard against overheating and protect the battery core during accidents.”

Source: Fraunhofer Institute for Machine Tools and Forming Technology IWU

.

[ad_2]