[ad_1]

<

section class=”MuiBox-root css-2cwqhs” data-id=”page-content” data-og-area=”article-blocks” id=”incArticle”>

Lotus

Insightful Discussion

Matt Windle: The advantageous aspect of Geely’s management of its range of firms is the willingness to explore new horizons while steering the course, without fully intervening. We retain the ability to coordinate our destiny and align our trajectory with board and CEO approvals [Fengqing Feng, who also serves as Chief Technical Officer of Geely Auto Group – Ed

TD: How is the sharing of technological innovations coordinated among the Geely Group brands?

An extensive range of components is readily available within the group, akin to a supermarket shelf. These technologies span across the consortium. Additionally, exclusive technologies from Lotus that the group desires to exchange. An uncomplicated analogy is comparable to entering a supermarket elsewhere, payments required for access. Conversely, we stroll into this figurative supermarket, evaluate the offerings on display, and procure them if necessary. We acquire licenses to share the technology. We have engaged with Volvo to license certain components, using Volvo parts in the Emira, such as the column stalks.

Internally, collaborative sessions on innovation and technology-sharing are conducted within the group, focusing on forthcoming developments. For instance, in crafting the Type 131 [Emira], we explored the four-cylinder engine. We assessed the consortium initially but concluded that further refinement was essential from our end to tailor the engine to our sports-oriented requirements. Simultaneously, we explored engine options.that are available on the market. When AMG expressed their willingness to collaborate with us on this project, it’s quite challenging to overlook it. It’s truly an outstanding engine.

TD: Before assuming the role of managing director, were you in charge of engineering the Emira? What was the initial directive?

Regarding the Emira, I believe we had a solid foundation with the Evora platform and its dynamics. Although everything has been revamped on the chassis, it essentially follows those fundamentals. For those who have driven an Evora enthusiastically, the dynamics of the Emira represent a significant upgrade. However, we aimed to appeal to a broader audience beyond our existing customer base. We had to consider ergonomics, comfort, and convenience. Today, individuals expect seamless connectivity in their vehicles without the hassle of dealing with cables stored in compartments like the glove box.

Lotus Emira, Lotus Cars

TD: In your opinion, what are the engine options available for the Emira?

One of the most frequently asked questions has been about the preferred engine choice. I usually amuse people with my response, being from Essex, I have a fondness for turbos.

TD: I see. I remember watching that particular show, The Only Way is Essex.

The noteworthy aspect about these engines is that they endow the two cars with distinct characteristics. If one’s budget allows, having one of each engine configuration would yield two distinct car personalities.

I find the turbo particularly appealing as it imparts a lighter feel and enhanced agility. Although there is some lag present, it is tolerable. Additionally, only the I-4 version offers the DCT, and many enthusiasts in the U.S. prefer the manual transmission for a more engaging driving experience, hence opting for the V6.

TD: There is a substantial demand for manual transmissions, yet the Emira, being a sports car, is delving into a realm where the 2.0-liter Mercedes-AMG M139 has not ventured before. It seems like a fitting match for such a vehicle.

Indeed, it’s intriguing that this engine resides at the rear, aligning well with our design philosophy. The synergy between the engine and our dynamic aspirations is remarkable. The engine performs admirably, and its tuning complements the vehicle superbly. I am genuinely enthused about this pairing. It’s also worth noting that this modern engine, the Toyota 3.0-liter 2GR-FE V6, is exceptional too. While it is sturdy, the AMG engine offers comparable reliability. Though we could have pursued an in-house engine development, I believe the synergy achieved by integrating a renowned powerplant with this exquisite vehicle is the right approach.

TD: How has your background in engineering influenced your managerial approach?

My engineering background is certainly beneficial, but I also have experience in the manufacturing realm. Beginning as an apprentice and progressing through various operational roles has endowed me with a profound understanding and rapport with the workforce. Many individuals on the production line appreciated the internal recruitment decision rather than an external hire. Being someone who comprehends the essence of Lotus and its values, I believe Geely deserves recognition for this insight. Geely comprehends the operational dynamics of the businesses within its portfolio and recognized the necessity for someone who aligns with that culture to assume a leadership role.

My background includes extensive engineering expertise along with operational management skills. I have overseen operational aspects of small businesses, which has instilled in me a penchant for meticulous planning and execution. I prefer a hands-on approach rather than prolonged decision-making processes by committee, opting to involve key stakeholders, make decisive choices, and swiftly proceed.

TD: Perhaps it’s just my perception as aoutsider, yet a common thread appears to connect Lotus as somewhat of a familial entity. The Beckers, including the former Roger [head of engineering for 43 years], and his son Matt [leading development engineer], who previously served for 25, 26 years at Lotus. [Head of vehicle dynamics] Gavan Kershaw has been a part of the team for 30 years. You commenced your journey there over 20 years ago before departing and eventually returning. Additionally, the rich legacy of sports cars and motorsports adds to this cohesive unit. Do you perceive any clash of cultures when steering the organization towards new horizons? The burden on your shoulders appears substantial in that aspect.

There is a mix of both. Initially, moving into [an executive position], I experienced some uncertainty regarding my place and self-assurance. Questions arose about perception and appropriateness for the role. However, transitioning into the role of [managing director] has proven to be more seamless. It feels as though this position was awaiting me, perfectly aligned with my abilities and aptitude.

Lotus

Individuals like Gavin, Russell, and other longstanding members embody this collaborative spirit. An encouraging environment fosters integration when individuals are provided with the autonomy to excel. Rather than dictating, I promote an environment where good ideas are welcomed and implemented effectively.

TD: As the Emira marks Lotus’s final internal combustion vehicle, have you encountered challenging conversations with representatives from Lotus clubs and enthusiasts, where you had to convey that “Just wait. You won’t be disappointed with the electric counterpart awaiting you.”

There have been instances where people expressed concerns, citing that “Chapman would not approve.” However, Chapman’s stance on powertrain technologies was pragmatic and geared towards achieving the best product possible. Despite differences in perspectives, we are driven by innovation and progress, propelling us forward.

Following our decision to embrace all-electric propulsion, legislations in regions like the UK accelerated, aligning with our vision. While some perceived us as forward-thinking, external factors also contributed to this evolution.

Having worked at Tesla for seven years and experienced the Mk1 Roadster firsthand, my insights surpassed the norm. Despite its dated technology, the Roadster was remarkable. Have you had the opportunity to witness its prowess?

TD: I recall, approximately in 2011, if memory serves me right.

Indeed, the initial experience of the Roadster was exceptional. Reflecting on its technology then and the subsequent advancements underscores the journey of technological progress. Witnessing the pioneering work on the upcoming sports car [Type 135] has left me awe-inspired. It promises to embody the quintessence of Lotus: elegance, agility, and exceptional performance. These values, including lightweighting, dynamic prowess, and aerodynamics, have been ingrained in our DNA since Chapman’s era.

TD: Is this the progression from the Project LEVA initiative?

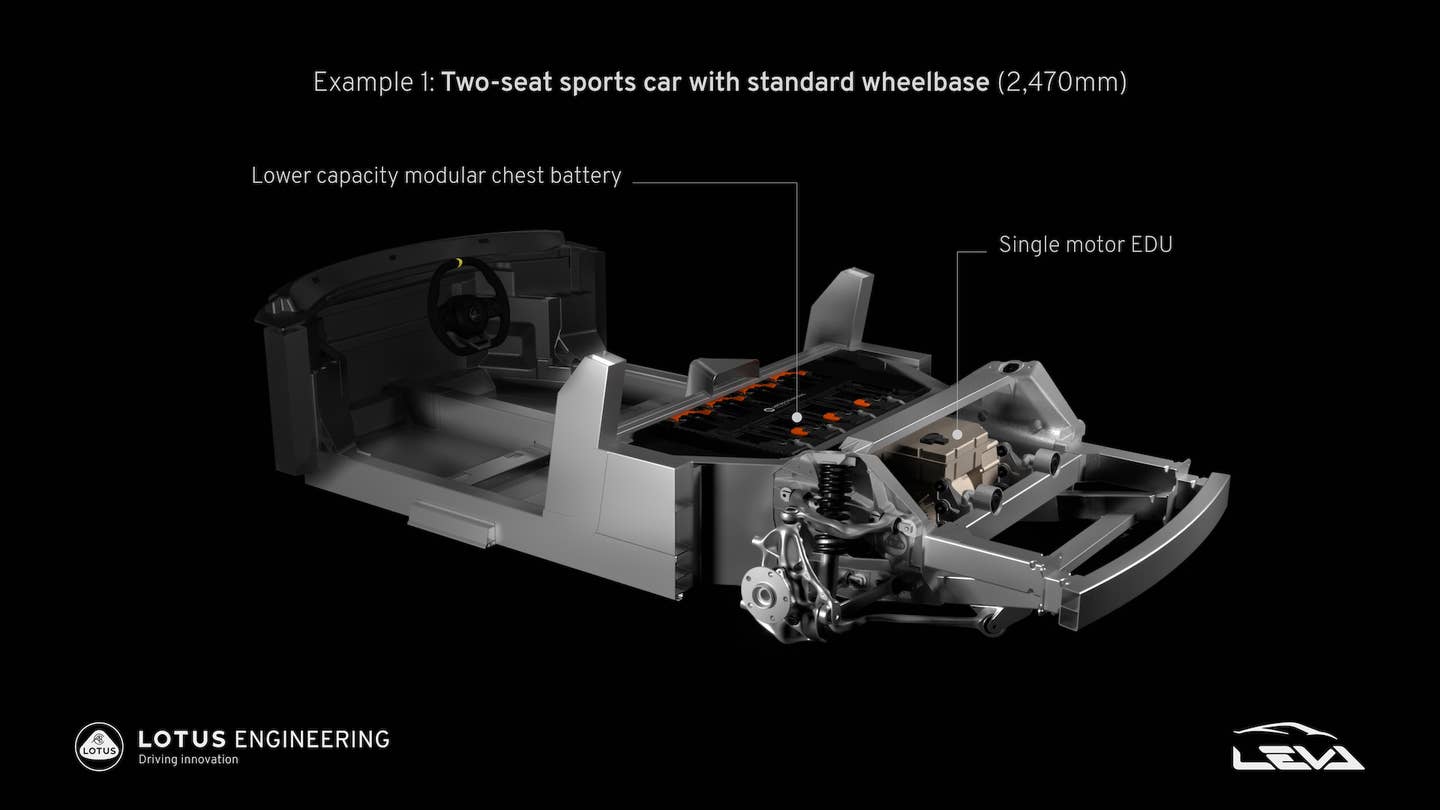

Project LEVA stemmed from a collaborative effort involving funding from the UK government and local suppliers. The aim was to devise a simple yet efficient structure integrating batteries within the frame, reducing excess weight by leveraging castings and extrusions.

The challenge posed for Type 135 is to maintain the same weight as the Emira while transitioning to electric propulsion. This necessitates a novel approach, pushing the team to think unconventionally, and the…the significant reduction in weight achieved through Project LEVA compared to our current status is remarkable.

Lotus Engineering: Lightweight EV structure for future electric cars., Lotus Cars

The platform is not yet part of our immediate product roadmap. However, its design allows for such versatility. Initially, we will focus on developing a two-seater layout with different body variations. Additionally, close collaboration with our OEM partners regarding the utilization of this platform for their models aligns with our product strategy and the vision of Lotus Engineering. This approach enables customization of wheelbases to cater to specific market segments desired by both the OEMs and ourselves.

TD: When crafting an enthusiast-oriented electric vehicle with an engaging driving dynamic, what are the primary advantages and challenges associated with incorporating an EV platform and drivetrains?

Our objective is to design aesthetically appealing vehicles. For our sports cars, achieving a low-slung profile is paramount. While positioning batteries at the base could enhance the center of gravity, it compromises the desired roof height and overall silhouette. Placing batteries lower would result in a taller car, ranging between 1,300 to 1,400 millimeters, whereas our target is to remain closer to the 1,200 millimeter mark or even lower if achievable.

Moreover, the mid-mounted configuration featured in the Evija, which we intend to continue with in upcoming models, strategically distributes the weight in a manner that aligns with Lotus’ expertise in managing weight distribution. Aerodynamics, driving dynamics, and weight optimization are pivotal aspects of our design philosophy.

TD: In the realm of engineering, balancing packaging constraints with dynamic performance requirements can be a challenging task. How do you navigate this complexity?

Packaging considerations hold significant importance. One of the key areas for optimization involves selecting the lightest and most efficient motor capable of delivering the desired performance. Crafting BEV sports cars presents a unique challenge as consumers seek a blend of performance and range. Balancing these aspects while ensuring peak performance is a delicate equilibrium we strive to achieve.

TD: Reflecting on your tenure at Tesla, are there lessons or insights that have informed your current approach?

My experience at Tesla emphasized a particular ethos rather than product specifics. It revolved around the willingness to make prompt decisions without hesitance. This approach heavily influences my management style – emphasizing constructive discussions, swift decision-making, and agile progress onto the subsequent tasks.

For Lotus, maintaining a similar ethos is paramount due to our identity as a boutique firm rather than a corporate giant. To remain competitive, innovation and agility are crucial. Staying abreast of rapidly evolving technologies is essential to prevent product obsolescence before reaching the market.

Elon Musk’s preference for in-house operations was notable during my time at Tesla. His conviction in internal capabilities for superior outcomes resonates with our aspirations. While we do not possess the same scale, identifying appropriate partners remains pivotal in realizing our envisioned vehicle.

TD: Historically, motorsports have been catalysts for innovation in vehicle dynamics and performance. However, this trend appears less pronounced in the realm of EVs. Could you elaborate on your involvement with Extreme E, where new frontiers are being explored?Jenson Button: Do you consider the innovative concept of the upcoming generation of Formula E vehicle? What is the current status of motorsports from your perspective?

At this point, our focus lies on collaborating with Button and Extreme E under Lotus Engineering to enhance their offerings. This direction could potentially lead us towards the SUV sector, aligning well with Extreme E’s domain.

Our ethos has always been to race our creations, with our current emphasis on GT4. Consequently, we have plans for an Emira GT4 in the upcoming season, slated to compete across Europe, China, and America. Our aspirations are deliberately modest for now, but we are eager to see where this journey takes us.

Lotus Emira GT4, Lotus Cars

TD: Regarding partnerships, your existing alliance with Alpine is noteworthy. How do you approach strategic alliances in the current context? Is it primarily a matter of merging strengths, or do other factors come into play?

We believe in fostering synergistic collaborations that complement each other’s strengths. With Alpine, we’ve established a memorandum of understanding spanning three key areas: future product development, collaborative engineering services via Lotus Engineering, and potential ventures in the motorsport arena down the line.

Sometimes partnerships unfold as intriguing endeavors. An example is our affiliation with British Cycling during the Olympics. While this collaboration didn’t yield financial gains, it provided an avenue for technological innovations in bike design, resulting in multiple Olympic victories. Such initiatives align with our corporate social responsibilities, from full-fledged commercial partnerships to acts of philanthropy. The spectrum of opportunities is vast.

TD: Reviving Lotus Engineering holds significant significance. Personally, reminiscing about the “Engineered by Lotus” branding across diverse vehicles and encountering Lotus engineers at other automakers’ events underscores the pivotal role of Lotus Engineering. What are the strategies not only for external tuning projects but also for broader engineering applications?

My vision for Lotus Engineering is to reclaim its former prominence. In earlier eras, the value of Lotus Engineering may have been undervalued. Leveraging my background in engineering, having led Lotus Engineering in various capacities preceding the Managing Director role, grants me a nuanced perspective of the business landscape. The market is dynamic and fiercely competitive, offering both challenges and prospects.

Our ongoing projects span a diverse range, encompassing advancements in engine technologies, software development, ECUs, materials, and other domains we previously excelled in. We currently house four battery testing facilities in the UK Midlands for cell modules, along with EV training initiatives. Our efforts extend beyond conventional mechanical pursuits, with established test cells for gasoline and electric drive units at Hethel. Focus areas also include vehicle dynamics, cockpit design, and cutting-edge acoustics innovations, catering to the evolving trends post-EVs era.

The distinguishing feature when it comes to Lotus Engineering is our capability to manage the entire process from a conceptual drawing to assembling a road-legal car, and everything in between. You have the option to utilize our services as a comprehensive solution provider, or select specific stages within the process.

TD: It might be evident, but could you elaborate on how collaborating with other companies could fuel innovation internally at Lotus Engineering?

Certainly, by engaging with external entities, we not only grasp their objectives but also gain the ability to initiate programs within our organization. For instance, through the BattCon initiative focused on battery testing, we will assess batteries from external sources using our facilities. This process allows us to enhance our understanding of performance, durability, and other critical aspects.

Furthermore, this practice ensures that our engineers remain sharp and motivated. The environment is abuzz with new products and technologies, inspiring our team to produce innovative solutions. They are actively participating in academic forums, conferences, and knowledge-sharing activities. This not only showcases our expertise but also facilitates a reciprocal learning process.

The innovative products we introduce also serve as a marketing tool for Lotus Engineering. Our integrated approach ensures that there is a seamless exchange of technology and creativity between the product development team and the engineering team. By having common leadership overseeing both areas, we achieve a cohesive strategy that encompasses technological advancements and commercial viability.

Lotus

TD: That’s disappointing.

I must say, it was an early model, but it promises an exceptional driving experience. I had the chance to ride it at Goodwood, and the thrill from start to finish was unparalleled. It’s an experience that I believe everyone should have the opportunity to encounter.

The testing program is progressing smoothly, with two vehicles currently in Italy undergoing high-speed tests to validate their performance capabilities. The advancements in battery technology provide confidence that we will deliver a superior product when these cars enter production early next year. Additionally, the sales projections are promising.

TD: You mentioned Italy and high speeds. Are you referring to Nardo by any chance?

I couldn’t explicitly confirm, but yes.

TD: In the realm of electric vehicles, do you believe hypercars serve as a stronger catalyst for innovative engineering compared to competitive motorsports? Do you foresee any shifts in this dynamic?

I envision that integrating these high-performance cars into specific motorsport events like Le Mans electric could elevate the essence of innovation. Operating a vehicle exceeding 2,000 brake horsepower is a remarkable engineering achievement, yet the driving experience remains quintessentially Lotus—a fusion of agility and precision that defines our brand.

TD: It appears that motorsports are yet to fully embrace EVs. A comprehensive league that embodies our desired features for EV racing is still lacking.

Lotus Engineering collaborates with F1 champion Jenson Button’s Extreme E team., Lotus Cars / JBXE Racing / Steven Tee

Extreme E serves as a prime example, wouldn’t you agree? It goes beyond sheer racing; there’s an environmental aspect along with the introduction of new products. It’s on a mission to reach diverse locations, making it a sustainability endeavor. However, the element of unpredictability surrounding product performance adds a captivating layer to the racing series. My belief is that soon we’ll witness races featuring EV saloon cars, albeit in what manner is uncertain. I am more than willing to provide 10 Evija vehicles to anyone eager to establish an Evija series immediately.

TD: For an individual unfamiliar with Lotus Group’s current standing, what are its constituent components and how do they collaborate?

The Lotus group will be divided into Lotus Cars and Lotus Tech, the latter being the Chinese division. Both entities report to the same CEO. Lotus Cars oversees the design, engineering, and production of sports cars in the UK, including motorsport and Lotus Engineering. Conversely, our counterparts in China primarily handle the engineering and manufacturing of lifestyle cars, such as the Type 132 SUV, despite their UK-based design. Our ultimate goal is to elevate Lotus into a globally recognized premium automotive manufacturer, aiming for high tens of thousands in production volumes compared to the current low thousands.

In the end, we will establish production facilities across two countries and continents. The UK will be the production hub for sports cars, while lifestyle cars will be exclusively manufactured in China. All our vehicle models are universally applicable. Acknowledging past gaps in U.S. market service, we assure that all our models are designed for global acceptance. Although the Evija stands as a distinctive case, from Type 131 [Emira] onwards, our vehicles will cater to a worldwide audience.

TD: This is a remarkable leap forward. How has this altered your strategic perspective? How are you preparing to tackle the challenges of mass production?

Embracing this shift entails adopting a fresh approach, especially in crafting products that resonate with potential consumers. For a high-volume sale, the understanding and appeal of the vehicle are pivotal. If the product fails to connect with customers, it may hinder sales opportunities.

Equally crucial is our commitment to staying true to our brand essence while developing products. It necessitates a delicate equilibrium. Our strategy involves analyzing competitors, market segments, and growth areas. The upcoming Type 132 model, for instance, is tailored to capture the burgeoning SUV market segment. Although this path has been trodden before, our vehicle boasts contemporary features, abundant technology, aesthetics, and aerodynamic elements. When you lay eyes on it, its Lotus DNA is unmistakable. Building brand recognition and trust remains paramount. Starting our journey in 2017, many perceived Lotus as a relic winning Formula One in the ’70s, unaware of its current status. Our focus lies in fortifying our brand image.

Revamping our global retail network, integrating new customer intelligence systems, and sourcing the right talent are essential steps. Expanding our presence, particularly in the U.S., is a priority, acknowledging the inconvenience faced by customers in distant locations. We initiated a revitalization process in 2017, focusing on refining management, processes, and strategies. The subsequent years centered on implementing the necessary changes and now we witness the fruition of those efforts.

The pace of our advancements is swift. Our aspirations are as ambitious as any undertaken, particularly in terms of production capacity. We maintain confidence in accomplishing our objectives.

This interview has been edited and condensed for clarity. Have a lead to share? Reach us at tips@thedrive.com.

[ad_2]