The 2023 Chevrolet Colorado has completely dropped six-cylinder and diesel motors and now exclusively employs the 2.7-liter turbo four-cylinder from the Silverado. This switch has raised doubts among truck purchasers – is there truly a substitute for engine size or diesel power? Is General Motors merely delivering trucks propelled by feeble time bombs? According to the individual overseeing the engine’s creation, that’s far from the truth. He actually went to the extent of labeling it one of the most resilient engines General Motors has ever constructed, and that certainly speaks volumes.

This level of confidence would be challenging to trust if it wasn’t coming from Kevin Luchansky, GM’s assistant chief powertrain engineer. During the unveiling of the new Colorado this week, Luchansky discussed the diesel-influenced design components and trial routine of what he describes as “one of the most enduring engines ever produced by GM. It’s truly remarkable.”

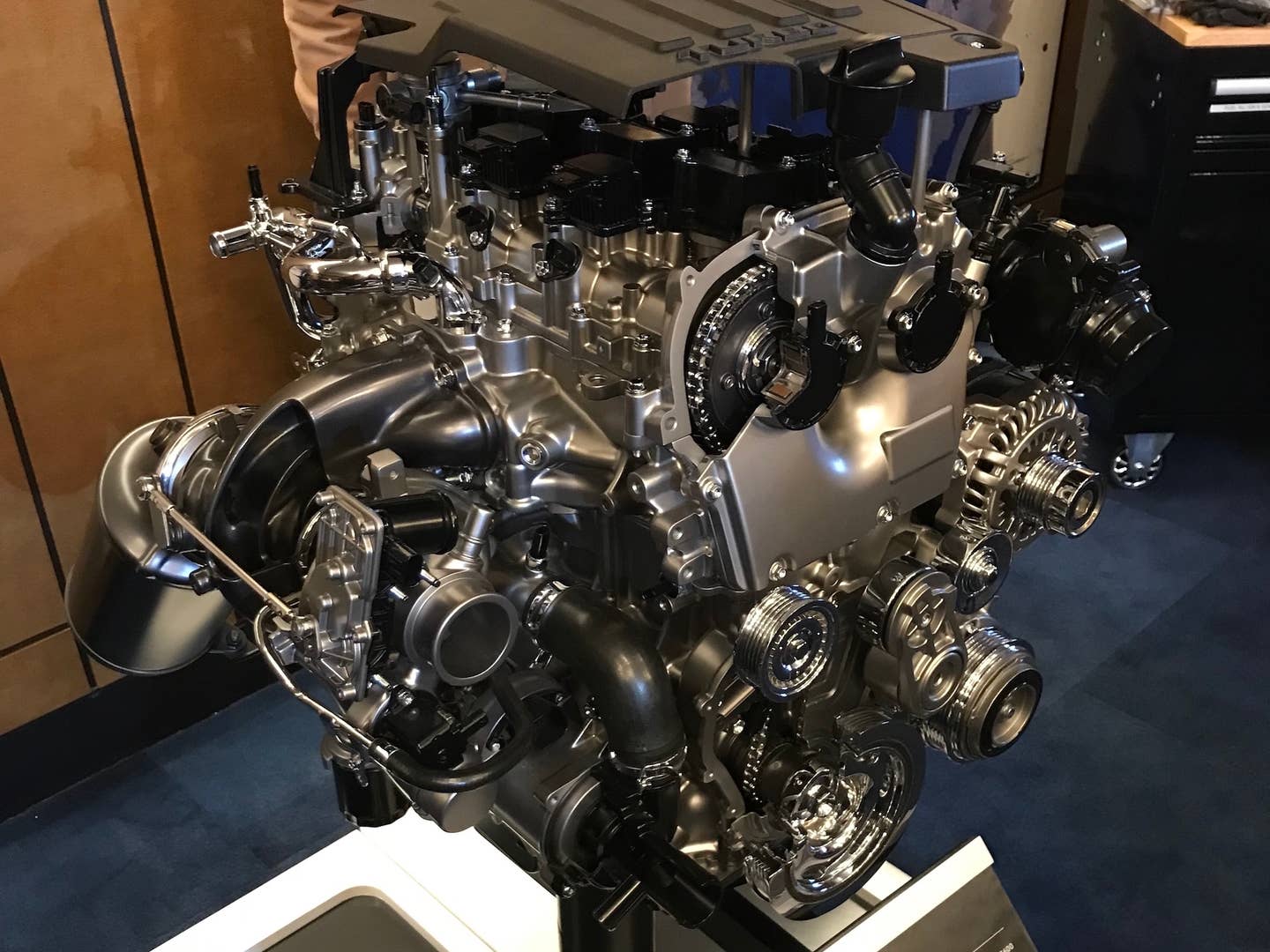

GM’s 2.7-liter turbo four-cylinder in the 2023 Chevrolet Colorado Trail Boss. James Gilboy

Despite Luchansky’s assurance, it’s crucial to acknowledge the concerns of truck owners regarding this powertrain. At 2,727 cc, it’s only surpassed by Ford’s 2.7-liter Ecoboost V6 as the smallest full-size pickup engine, and the third tiniest among midsize trucks. It operates with a relatively high compression ratio of 10:1, with boost pressures reaching up to 27 psi. This leads to double the cylinder pressures when compared to an equivalent naturally aspirated V8, like the 5.3-liter small-block it effectively replaces in the larger Silverado.

This setup could potentially result in significant knocking issues, especially given that the 2.7L is engineered to run on regular 87-octane gasoline. However, Luchansky emphasized that it will endure whatever challenges it faces because he implemented diesel engine methodologies that bolster its endurance during rigorous testing.

While labeled as an all-aluminum engine in name (maintaining a light long-block weight of 331 pounds), it incorporates iron cylinder sleeves cast into the block during production. Despite this, the material employed is more contemporary, ensuring it resists wear unlike many older cast-iron blocks.

GM’s 2.7-liter turbo four-cylinder truck engine cutaway. James Gilboy The Drive / James Gilboy

The pistons are also comprised of an aluminum alloy, featuring machined heads to optimize material characteristics, and cast-iron ring carriers to resist the high cylinder pressures. Instead of conventional molybdenum-coated iron rings, the 2.7L employs diesel-grade steel rings with PVD coatings, lowering friction and decelerating wear.

The considerable torque output of up to 430 pound-feet from this four-cylinder necessitates robust bearings. Hence, Luchansky and GM’s engineering team decided against adopting common bi-metal rod bearings—composed of an aluminum alloy over a steel backing—and opted for tri-metal bearings with an additional copper alloy layer to enhance heat dissipation.

The outcome is an engine capable of withstanding prolonged abuse, as per Luchansky’s description. GM rigorously tested the 2.7L on a dynamometer at wide-open throttle continuously “for weeks,” leading to the pistons of prototypes glowing and wrist pins turning purple due to heat. Additionally, GM has disassembled engines taken back from customers who operated them without oil, all to identify potential failure points, the resolution of which has notably extended the engine’s durability. As a matter of fact, these enhancements have potentially averted situations where severe conditions might not even erase the manufacturing logo from the inside of the bearing.

“Compared to the past, we are now running 25 percent longer,” Luchansky commented on the engine’s enhancements. “Over the years, we have reinforced and enhanced various components. This is why we can push the torque to such high levels.”

Luchansky and his team understand, however, that they cannot impose this engine onto truck buyers; it must earn its reputation independently. “It needs to prove itself, and it is doing just that,” he asserted, highlighting that GM has already sold over 300,000 trucks featuring these engines, with overwhelmingly positive feedback.

“Those who own them absolutely adore these engines,” shared Luchansky. “Dealers rarely encounter issues with the 2.7L during service.”

Ultimately, the true test will occur in real-world scenarios, where individuals may overlook oil changes and overload trailers. GM’s efforts must justify themselves, determining whether the 2.7L will win hearts or possibly tarnish its reputation among consumers. Judging by Luchansky’s enthusiasm about GM’s creation, it seems we should anticipate nothing less than exceptional.

Do you have a tip or question for the author? Feel free to contact them at: james@thedrive.com