[ad_1]

According to Xavier, the initiative is still a work in progress, yet adept individuals in bodywork should manage to utilize the printed files for completing their hardtop with minimal effort. The entire hardtop negative could be printed for about $30 in material costs. A total of 1.5 kilograms of ASA filament was consumed during the printing process, spanning six days and eight hours. Additional expenses included roughly $100 for fiberglass mat and epoxy, about $60 for Bondo, $12 for a window seal roll, $150 for an acrylic window, and sundry miscellaneous costs. Altogether, the final cost of the unpainted hardtop neared $360—substantially cheaper than a $1,500 mass-produced fiberglass top or a $2,500 OEM variant. Opting to print it yourself would tack on an extra $100 to the cost, the amount Xavier is requesting for his 3D printable model. In case a printer is needed, an affordable Ender 3 could be obtained for as low as $99 during special sales at outlets like Micro Center.

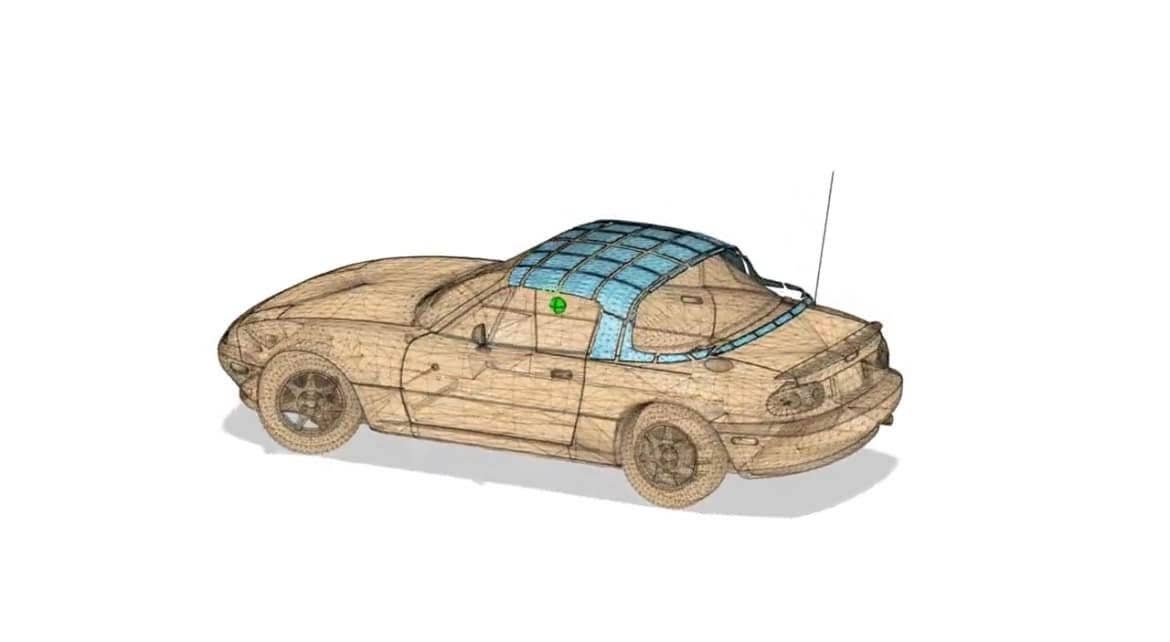

If you lean towards a fastback design, here’s more good news: another Miata aficionado has crafted a 3D printable fastback model. The concept behind the fastback mirrors that of the hardtop (printing the plug, constructing the actual fiberglass layer on top) and is thoroughly documented on the Hutchins Racing YouTube channel.

This demonstration of DIY ingenuity showcases not only the extended longevity of enthusiast vehicles through 3D printing but also how this method renders them more cost-effective and customizable within a domestic setting. If you wish to delve deeper into this topic (or require some persuasion to invest in your inaugural 3D printer), I’ve explored the plethora of fascinating applications of 3D printing within the automotive enthusiast realm previously, complemented by my colleague Peter Holderith’s comprehensive guide on initiating the process of crafting and 3D printing your personalized accessories post our participation in The Drive’s Great Ford Maverick 3D Print-Off.

If you have any tips or queries for the author, feel free to reach them directly at: rob@thedrive.com

[ad_2]