[ad_1]

Regardless of where you stand concerning the adoption of electric vehicles, when it comes down to it, electric cars are marvels of engineering, and there’s a certain cool factor about them. Electric motor cooling has not always been top of mind for many, given that EV motors operate at efficiencies exceeding 90%. One may wonder how much energy they could potentially be wasting. However, my perspective changed when I came across an opinion piece penned by Aitor Tovar, the chief engineer overseeing eMotor development at GKN, a company with a wide array of drive units currently in use in hybrids and fully electric vehicles. In summary: While an oil-cooled motor may require a higher upfront investment, it provides significant advantages to the overall vehicle performance.

My initial reaction was one of skepticism: “Is a person involved in motor sales promoting the switch to more expensive motors?” Cue the surprised YouTuber expression. However, it turns out that Tovar’s perspective is not unique, and it represents a well-informed viewpoint worth deliberating. Electric vehicles are intricate systems, and a thorough evaluation is necessary to determine if the benefits outweigh the costs. Delving into this topic also provides a chance to delve into the fascinating world of electric motors. For those not enamored with electric cars, consider this a discussion about power tools.

2025 Porsche Taycan Turbo GT. Porsche

A Brief Overview of Electric Motors

The process of winding a wire around an iron nail and subsequently connecting the wire ends to a battery results in an electromagnet. This science experiment classic outshines Billy Sedgwick’s papier mâché volcano. Electric motors—whether AC, DC, brushed, brushless, synchronous, or otherwise—all leverage electromagnetism to convert electrical energy into mechanical power. These motors utilize metal windings as the electromagnet. By altering the current’s direction, the polarity of the magnets changes, thereby attracting and repelling the rotor to generate torque. As electricity flows through the motor, resistance in the materials leads to them heating up as their microscopic vibrations intensify. Additionally, there is heat production in the permanent magnets. Although not substantial, these factors cumulatively contribute to heat generation.

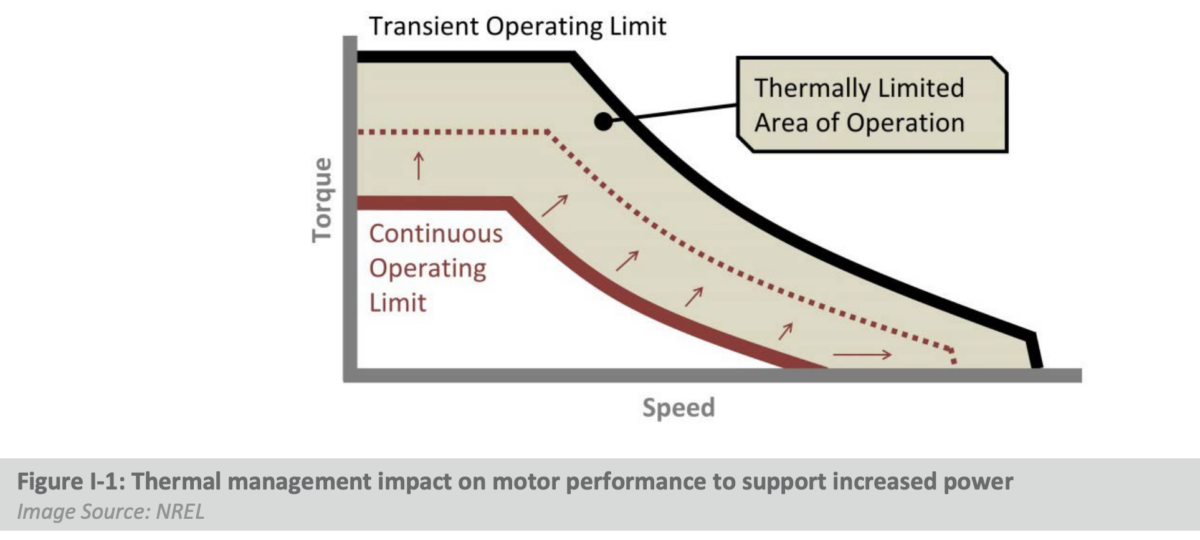

Similar to internal combustion engines, electric motors are designed to function within a specific temperature range. While temperature fluctuations may exist among various components, the windings’ temperature should typically fall between 100°C and 150°C (212°F–302°F). As the temperature rises, so does the resistance in the windings. Thermal expansion can further diminish efficiency by altering tolerances inside the motor, which can lead to increased temperatures and eventual permanent damage.

No Explosions, so Cooling Seems Manageable, Right?

Internal combustion engines exhibit significant inefficiencies, partially due to the dissipation of energy through the exhaust. However, they also circulate coolant through their blocks and heads to dissipate heat, which subsequently goes through a radiator before being released into the environment. The cooling process itself indicates inefficiency.

Even the most efficient internal combustion engines struggle to achieve 50% efficiency at peak torque, with a majority of gasoline engines operating in the 20% range. On the contrary, the average electric motor surpasses 90% efficiency. Well-optimized motors operating at full capacity can even approach 98% efficiency, not to mention the ability of EVs to reclaim energy through regenerative braking. While they may sound akin to cordless power tools during operation, any opportunity to defy the Second Law of Thermodynamics is exhilarating.

At times, sacrificing a marginal level of motor efficiency for the sake of the entire system’s efficiency proves to be a worthwhile trade-off. A smaller motor may need to exert more effort and generate additional heat compared to a larger counterpart, but the advantage lies in weight savings. Furthermore, a larger motor running at low power levels is less efficient than a smaller motor operating within its optimal range. It all boils down to striking a balance.

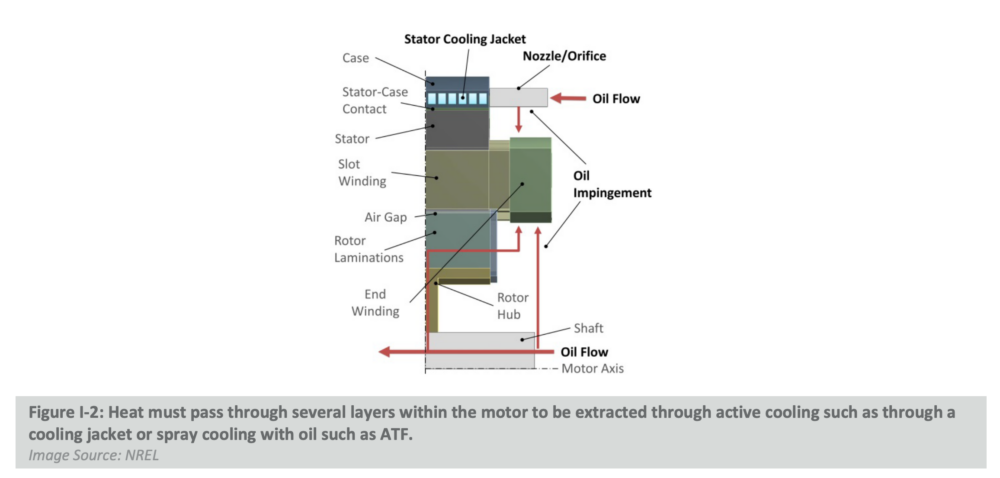

The type of oil cooling advocated by Tovar for electric motors mirrors what is typically observed in high-performance internal combustion engines. The oil circulates inside thedrive through logs, and misted on parts where logs aren’t feasible. If you have ever observed an internal combustion engine with oil squirters targeted at the undersides of the pistons, those are present for cooling purposes rather than lubrication. Indeed, you can saturate the base of the motor with oil for cooling, but akin to an engine, splattering moving components with oil creates parasitic resistance. This is among the rationales why high-performance engines employ dry-sump mechanisms. Studies suggest that the most efficient method to cool a motor is by combining pumping oil across the motor shaft and utilizing logs to convey oil to the exterior of the rotor through centrifugal force, coupled with oil squirters on parts such as the external part of the commutator or even the terminations of the windings.

National Renewable Energy Laboratory

You Desire to Insert What in My Motor?

Automobile glycol-based coolant is immensely effective, but an improper option for electrical apparatuses due to its excessive conductivity to be utilized inside a motor. Some motors do make use of traditional automobile coolant, yet solely in water jackets surrounding the external part, which isn’t remarkably efficient for cooling the complete motor.

Whatsoever you infuse inside a motor cannot be nonconductive, as it will accumulate a static charge when electrons amass on the surface of the liquid. Any coolant employed also necessitates exemplary lubricity since that is a derivative purpose. Oh yes—EV producers would cherish for this to be an enduring fill, hence it should comprise ample surfactant content to purge the system. It should not encompass oxides either. Did I acknowledge that the identical cooling loop will probably be employed in the gearbox, irrespective of whether it’s single or multi-speed? It’s a challenging task for one fluid to tick all those criteria, but it turns out that automatic transmission fluid (ATF) is essentially ideal.

Please allocate me a few expressions to discourse the tempest I can already envision brewing in the remarks. To be impartial, I am aware it’s likely to arise from both extremes. On one facet, Obi_Wan_GREENobi will be infuriated I’m backing the employment of fossil-fuel-derived fluids in EVs. Meanwhile, Darth_V8er is going to brandish his lightsaber as he taunts the tree-hugging hypocrites still requiring oil for their EVs. I’ll be the pivot of the bright and dark, Father@Motoris: Any sensible individual realizes humanity is not escaping from deceased dinosaur juice anytime soon. Nevertheless, we ought to be exerting a concentrated endeavor to restrict the extent of it we rely on. In this instance, we’re deliberating about a few liters of ATF for about a hundred thousand miles in a motor before being drained and recycled, juxtaposed with a gallon of gasoline to traverse 30 miles that’ll never be regained. May the force be with you.

Hooray, We Enhanced Motor Cooling. Then What?

Comparable to gasoline-propelled vehicles, EVs are outfitted with motors that scarcely exploit their total capability. Even accelerating onto a highway will solely employ half of the attainable power; if we’re referring to something like a Tesla Model S Plaid or Porsche Taycan Turbo S, the proprietor regularly won’t tap into more than 30% of attainable power. Nonetheless, manufacturers utilize larger motors so that those colossal performance figures can be upheld without overheating, just in case a customer genuinely takes their electric supercar to a track day. If we refine the motor’s cooling, though, we can downsize it. That not only conserves weight and space but also renders the motor more energy efficient at average power outputs.

National Renewable Energy Laboratory

Currently, oil-cooled motors find utility in the highest-performance EVs. Manufacturers are hesitant to invest in lower performance (read: lower priced) EVs and hybrids, although smaller automobiles would presumably derive the most benefits. As more vehicles embrace hybrid powertrains, maximizing system efficiency, maintaining costs at a low, and refraining from incorporating additional items in a vehicle’s maintenance schedule is going to be of paramount importance. Reverting to the original editorial that instigated this entire thing, if producers can utilize smaller motors and, in the scenario of hybrids, an existing cooling fluid loop in the vehicle, it offsets the expense of incorporating cooling equipment within the motor.

To delve more profoundly into the temperature versus efficiency debate, this document from Victoria University, Melbourne Australia provides valuable insights. And if you aspire to craft your own basic electric motor with items you likely have at home, check out this video.

Got tips? Send ’em to tips@thedrive.com

[ad_2]