[ad_1]

AEON Co., Ltd. (AEON), AEON KYUSHU Co., Ltd. (AEON KYUSHU), AEON GLOBAL SCM Co., Ltd. (AEON GLOBAL SCM), and Commercial Japan Partnership Technologies Corporation (CJPT) are set to enact measures to tackle societal concerns in the logistics industry and support carbon neutrality at the newly established AEON Fukuoka XD logistics center.

AEON has been dedicated to enhancing efficacy across all distribution stages, from procurement to sales, with the intention of optimizing logistical processes. CJPT has focused on dual aspects: logistical effectiveness, which it believes will not only resolve logistical challenges but also facilitate an immediate shift towards carbon neutrality, and the electrification of vehicles.

Collaboration between AEON and CJPT commenced at AEON Global SCM’s South Osaka RDC*2 in April 2021 as Phase 1. By merging AEON’s expertise in retail logistics with the TPS (Toyota Production System) philosophy, the companies aimed to visualize and enhance goods flow, leading to heightened loading efficiency through logistical center advancements and optimal delivery leveraging real-time data. This endeavor resulted in around a 10% enhancement in overall truck mileage efficiency and a 10% decline in CO2 emissions. Phase 2, starting in September 2022 in partnership with AEON KYUSHU, expanded the scope to involve wholesalers and suppliers, streamlining the entire supply chain from upstream to downstream via cross-industry initiatives.

For Phase 3, AEON and CJPT will work towards bolstering the efficacy of logistical efficiency by consolidating these initiatives at the new AEON Fukuoka XD logistics center, which is set to commence full operations on July 24, 2024. By promoting “vehicle electrification,” the companies aim to address logistical issues and achieve carbon neutrality, with a target of reducing CO2 emissions by 35% by 2030*3. Specifically, “logistics operations automation” will be integrated into efforts to decrease overall travel distance by optimizing operations within the logistics center and during deliveries, thereby reducing workload and boosting productivity. Additionally, the companies will actively pursue reducing CO2 emissions through the introduction of eco-friendly vehicle technologies such as fuel cell (FC) small trucks.

The companies plan to expand these initiatives across the entire supply chain, enhancing procurement logistics efficiency by integrating data with suppliers, and utilizing double-trailer trucks and collaborative transport for long-haul logistics. AEON and CJPT are committed to achieving carbon neutrality and addressing logistical challenges nationwide, thereby contributing to resolving society’s logistical hurdles.

Concrete measures based on the new logistics center “AEON Fukuoka XD”

| Categories | Initiatives | Target | Reduction in CO2 emissions |

|---|---|---|---|

| Logistics Efficiency Enhancement | Pursuit of efficiency through store-logistics integration based on TPS philosophy

|

10% reduction in total mileage | ▲10% |

Enhanced efficiency via data/automation technology in logistics

|

10% reduction in total mileage 30% increase in shipping capacity |

▲10% | |

| Vehicle Electrification | Cutting CO2 emissions using eco and vehicle technologies

|

15% of total vehicles | ▲15% |

| Contributing to Local Communities | Resolving logistical challenges

|

||

*1 Cross Dock = A logistics facility with the function of temporarily receiving and quickly delivering goods to the appropriate location.

*2 Regional Distribution Center = A logistics facility that stores fast-moving goods and supplies them to stores in the designated area through a cross-dock center in the designated area.

*3 Submitted on October 22, 2021―Japan’s NDC (Nationally Determined Contribution) as determined by the national government.

An Overview of the new logistics center “AEON Fukuoka XD” (a comprehensive logistics center consolidating ambient and cold storage functions)

Name: AEON Fukuoka XD

Location: 1-1-4 Minato Kashii, Higashi-ku, Fukuoka City, Fukuoka, Japan, T-LOGI Fukuoka Island City 1F-2F

Leased Area: 41,335.80 square meters

Improving work efficiency by integrating the TPS (Toyota Production System) philosophy

Successful collaboration between AEON and CJPT at the worksite

A case of efficiency improvement

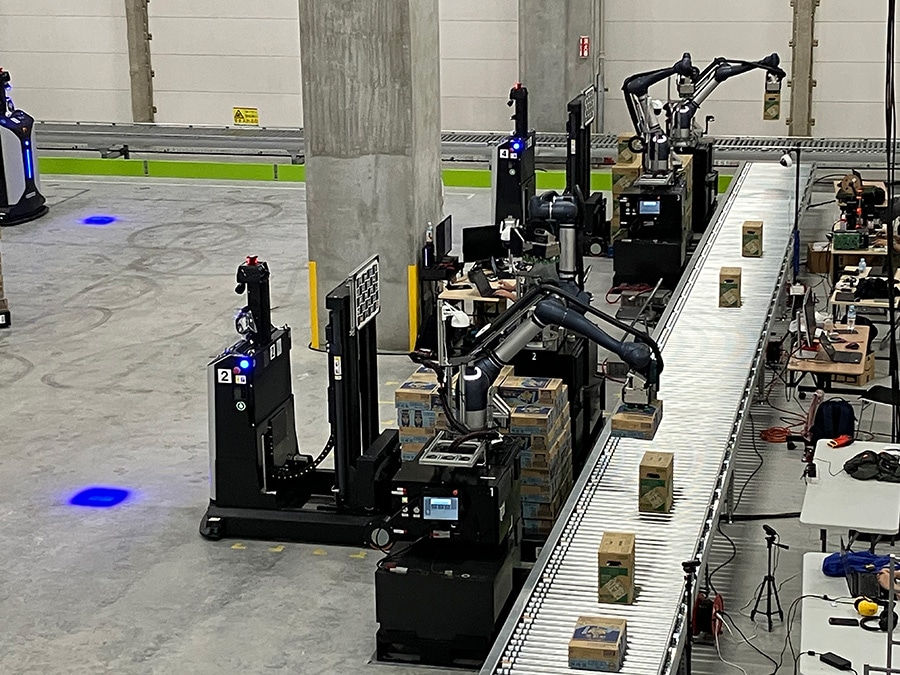

Automating logistics operations through the introduction of automated equipment

Automated pallet warehouse

Depalletizing arm robot

AI-operated remote Depalletizing arm robot

Remote unmanned forklift AGF

Next-generation AGV (Automated Guided Vehicle) transportation system

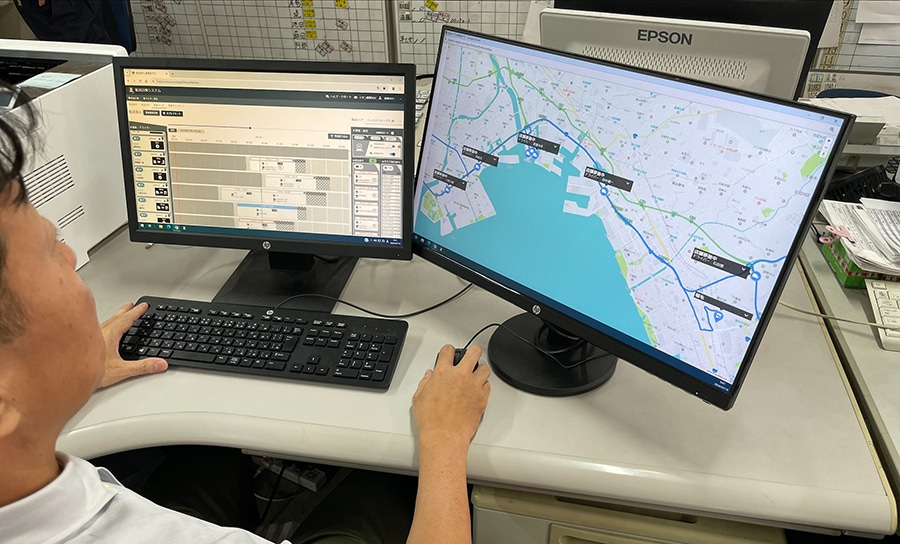

Connected delivery planning system (E-TOSS*4) utilizing real-time data and connected technology

Utilization of E-TOSS for dispatching

Dispatch planning visualization

*4 E-TOSS Developed by Toyota Motor Corporation based on CJPT’s concept

Utilization of FC small trucks

Zero CO2 emissions from hydrogen-powered fuel cell vehicles during operation

Utilizing the Fukuoka Prefecture Fuel Cell Truck Introduction Promotion Project subsidy

SOURCE: Toyota

[ad_2]