Sponsored by DuPont.

The automotive sector is undergoing a significant transformation, with electric vehicles (EVs) leading this change. The broader acceptance of EVs depends on several critical aspects: lowering costs, developing a strong charging network, and creating efficient, long-lasting battery packs that support rapid charging. As car manufacturers aim to compete with the affordability and efficiency of traditional internal combustion engines, the drive to create high-performance EV battery packs intensifies, with adhesives playing an increasingly vital role in their engineering and assembly.

Design Trends Influencing EV Battery Assembly

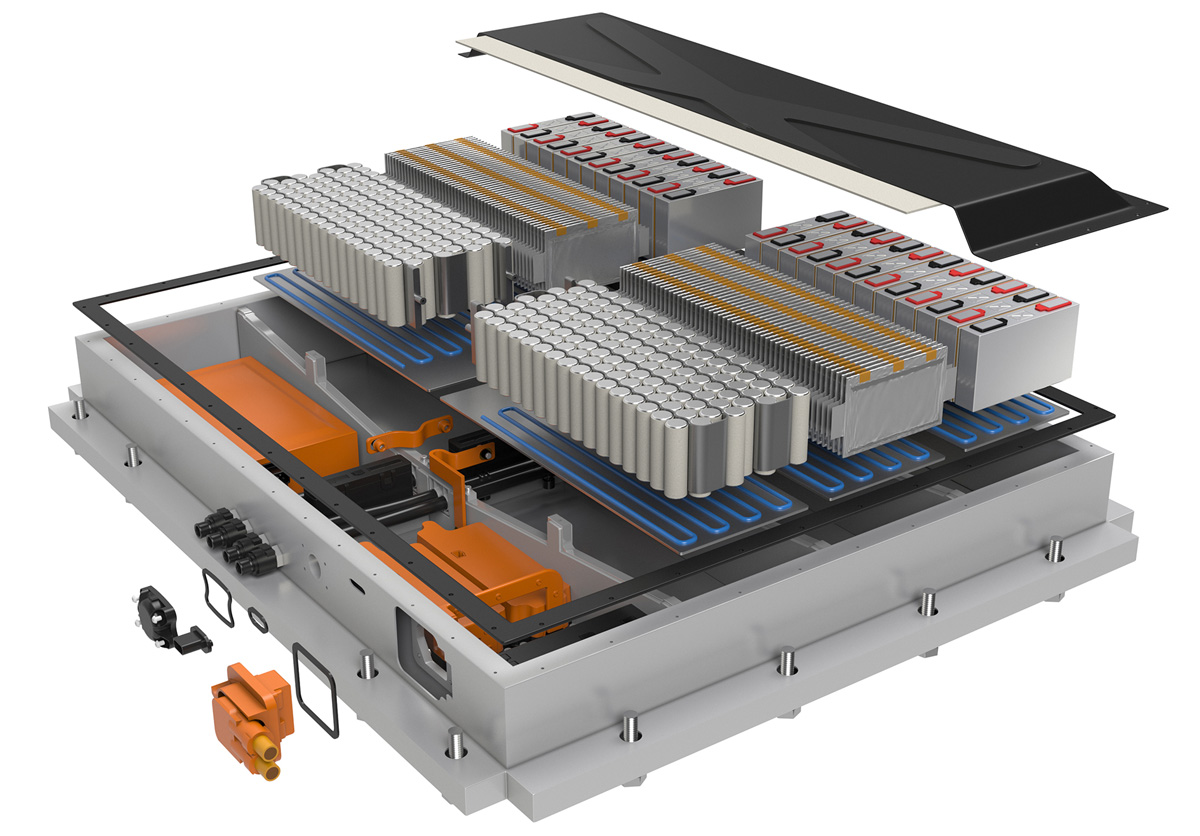

The design of EV battery packs is advancing swiftly as automakers and researchers work to improve performance, reduce expenses, and promote sustainability. Efforts are concentrated on enhancing energy density and decreasing costs per kWh, which has led to more streamlined designs that eliminate excess parts, weight, and size. However, these innovations might impact structural integrity and complicate battery replacement, disassembly, and recycling processes. Advanced adhesive technologies are beginning to provide solutions to these issues, paving the way for future EV battery pack designs.

Here’s a closer examination of the progression of EV battery technology:

- Cell-Module-Pack (CMP) designs combine individual cells within modules, a method that has become prevalent due to its robustness, ease of assembly, and serviceability. However, due to the increased number of components that CMP entails—which adds to cost and weight—automakers are now looking for designs that minimize parts to enhance energy efficiency and simplify production.

- Cell-to-Pack (CTP) designs embed battery cells directly into the battery pack by removing modules, which improves energy density and simplifies manufacturing. This emerging approach is gaining popularity for its cost-saving potential, but it requires advanced thermal management and durability, while the complex assembly process allows little margin for error.

- Cell-to-Body (CTB) designs integrate battery cells into the vehicle’s structure, maximizing space, reducing weight, and enhancing structural integrity. Early adopters are investigating CTB designs for their cost-effectiveness and lower part counts, though concerns about durability, recyclability, and safety remain significant.

The Advantages of Adhesives in Eco-Friendly Battery Assembly

As the demand for EVs rises, the necessity for sustainable and efficient battery assembly becomes increasingly urgent. Adhesives play a crucial role in EV battery production by offering numerous benefits.

- Enhanced Performance—They improve battery functionality by optimizing the thermal interface between battery cells and cooling systems, resulting in extended range and quicker charging times.

- Flexible Battery Design—Adhesives provide greater design versatility by bonding various materials, including composites, functional films, and metals. This non-destructive joining method maintains the structural integrity of components, enabling innovative battery designs that were previously impossible.

- Increased Energy Management for Safety—Safety is essential in EV battery design, and adhesives contribute to managing crash energy. They create consistent bond lines that improve the structural integrity of the battery pack and allow for wheel-to-wheel battery configurations that function well under crash conditions.

- Enhanced Structural Capability—With the increasing use of cell-to-body designs, adhesives provide the necessary bonding strength to replace modular walls and supporting structures.

- Improved Thermal Management—Effective thermal management is vital for battery safety. Thermally conductive adhesives and interface materials facilitate heat dissipation, preventing overheating during charging and operation. Over time, this ensures stable performance and extends battery life.

- Support for Zero-Emission EVs—By enabling lightweight designs and reducing panel thickness in vehicle structures, adhesives contribute to sustainability, resulting in considerable CO2 reductions of around 133 grams per kilometer driven.

- Refined Manufacturing Processes—Adhesives simplify manufacturing by providing rapid, cost-effective bonding and curing solutions, eliminating the need for surface pretreatments and enhancing speed, which leads to substantial cost savings.

New methods in battery assembly also favor the use of adhesives. Injectable adhesives lend themselves to modular battery frames, while debonding-on-demand solutions ease repair and recycling. Certain adhesives also cure on demand, which is ideal for flexible, resource-efficient manufacturing processes.

DuPont’s Solutions for Modern EV Battery Assembly

DuPont, with extensive expertise in EV battery assembly, is ideally suited to support the industry’s transition toward advanced battery designs. Our diverse adhesive solutions are tailored to meet specific challenges, delivering enhanced performance, safety, and sustainability.

- BETAFORCE™ Elastic Structural Adhesive: A 2024 R&D 100 award winner, BETAFORCE™ is tailored for various EV battery assembly applications, excelling in bonding pouch cells. It effectively bonds aluminum laminated film substrates without requiring primers or pretreatment—ensuring durability and sustainability. With up to 30% renewable and bio-based materials and room-temperature curing, this adhesive reduces the need for high-temperature processing, thereby lowering environmental impacts.

- BETAMATE™ Structural Adhesive: BETAMATE™ safeguards battery pack integrity through its stiffness, durability, and crash performance. It is instrumental in bonding and sealing battery pack housings and cooling plates, providing robust adhesion to aluminum alloys and composites. BETAMATE™ is also applicable in the emerging area of CTB designs, enhancing safety, corrosion resistance, and manufacturing efficiency.

- BETATECH™ TIM (Thermal Interface Material): This innovative solution is free from diisocyanates and silicones and effectively manages heat from high-density batteries during their operation and charging phases, maintaining thermal conductivity across a wide temperature range. BETATECH™ is designed for easy dispensing and joining, making it suitable for high-volume assembly processes.

Sustainability

At the heart of DuPont’s mission lies sustainability. Our adhesive solutions are developed to tackle critical challenges while enhancing the performance and safety of EVs.

- BETAMATE™ Broad Bake Adhesives: These adhesives contribute to reducing e-coat oven temperatures by 25°C, resulting in significant energy savings and shorter oven cycle times that enhance overall manufacturing efficiency.

- BETAFORCE™ 2800 TC: This adhesive not only maintains cooler temperatures in EV batteries during rapid charging to prolong battery life but also reduces the amount of raw materials needed by decreasing the number of components.

- BETATECH™ TIM: These adhesives feature a low pullout force, facilitating the easy removal of battery modules for repair, reuse, and recycling.

These product families are also available in room-temperature curing formulations. Oven-free bonding not only reduces energy consumption but also streamlines the assembly process.

Collaboration and Innovation: DuPont’s Centers of Excellence

DuPont values the importance of collaboration. Our Centers of Excellence and advanced engineering capabilities worldwide are committed to working closely with clients to foster innovation in EV battery assembly.

- Rapid Development: We boast formulation and testing expertise that allows us to validate new concepts and refine existing ones.

- Thorough Testing: To confirm performance, longevity, and safety of proposed designs, we expand small sample tests to module-scale testing within the battery system.

- Global Collaboration: Our teams work together across regions, functions, and businesses to deliver state-of-the-art solutions tailored to the specific needs of our customers.

Ready to Collaborate?

At DuPont, we see ourselves as more than just a supplier; we are a partner in innovation. If you’re looking to enhance your EV battery assembly process, we welcome you to partner with DuPont to explore how our adhesive solutions can help you meet your objectives.

.