[ad_1]

Mitsubishi Fuso Truck and Bus Corporation (Headquartered in Kawasaki City, Kanagawa Prefecture, led by President and CEO Karl Deppen) has initiated a project called the “Supply Chain Control Tower” (hereafter referred to as “the Project”). The aim of this initiative is to enhance the efficiency of inbound parts logistics management through digital transformation.

The company intends to automate various processes while also monitoring the vessels transporting parts and estimating their arrival times at factories in Japan in real time. The newly implemented functions will replace tasks previously performed by logistics operators, resulting in substantial reductions in both working time and costs.

Background and Objectives of the Project

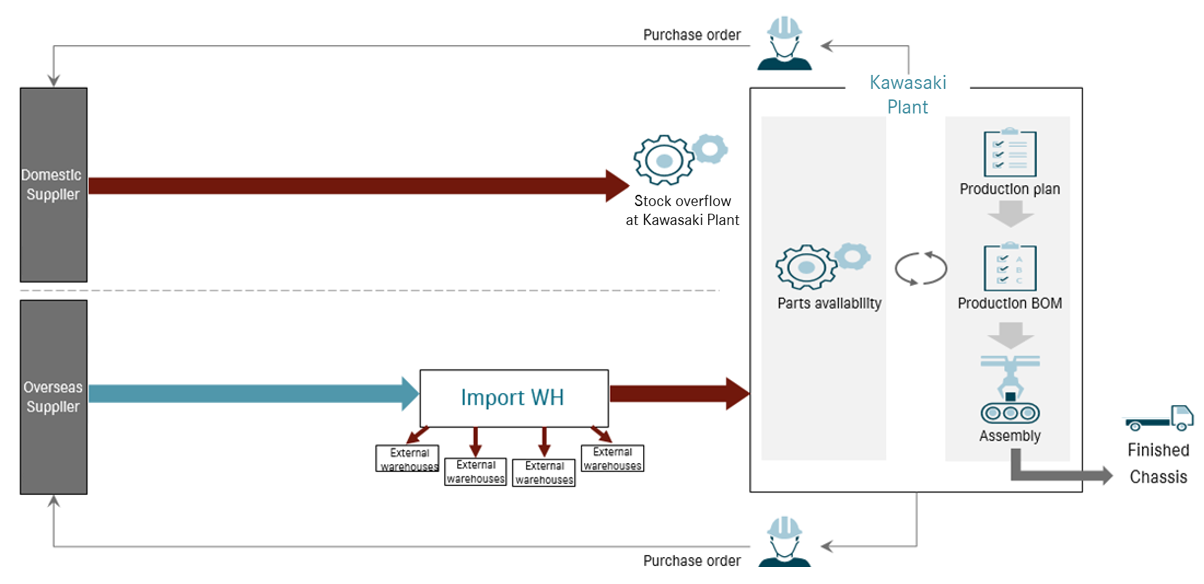

Each truck or bus is assembled using over 10,000 individual parts. Manufacturing components are delivered daily from hundreds of suppliers, both domestic and international, to MFTBC’s production facilities. The ordering and transportation of parts are organized weekly and monthly based on several factors, including the assembly lines’ production capacity and parts availability at the logistics warehouses. Currently, logistics operators manage the daily oversight of incoming manufacturing parts.

Through the Project, MFTBC aims to optimize work efficiency with digital transformation (DX) across the entire inbound parts logistics cycle, which includes ordering vehicle parts, verifying stock levels, planning production, and manufacturing vehicles.

Recent supply chain disruptions in the commercial vehicle sector, caused by factors like COVID-19 and semiconductor shortages, have highlighted the need for this project. It is expected to enhance the stability of logistics and production systems by enabling a more agile response to these challenges.

Part of the Project involves the “IBL*1 Control Tower”*2, a system that MFTBC has employed since 2023 to digitally streamline the transportation of manufacturing parts from domestic suppliers.

The “IBL Control Tower” uses real-time tracking to forecast the arrival of vehicles by analyzing location data and traffic information for trucks transporting components to MFTBC factories.

*1IBL: Inbound Logistics

*2 For additional information, please refer to MFTBC’s press release dated December 26, 2022.

[Image of inbound parts logistics]

Enhancements in Parts Ordering Operations

To optimize its logistics functions, MFTBC has refined its parts ordering processes by incorporating automated monitoring and adjustments to various procedures.

Manufacturing parts are typically ordered at specific intervals based on supplier locations. Previously, operators relied on manual calculations to determine order quantities by considering the production line’s status, current inventory, and production schedules. The newly deployed software automates inventory monitoring through a cross-check of vehicle production timelines and parts ordering strategies.

This in-house developed system automates the entire process of parts ordering, calculation, and data entry, thus expanding the scope of monitoring. This enhancement in capacity is expected to lead to a reduction in excess inventory and lower storage costs for parts.

Real-Time Monitoring of Transport Status and Estimated Arrival Times of Imported Parts

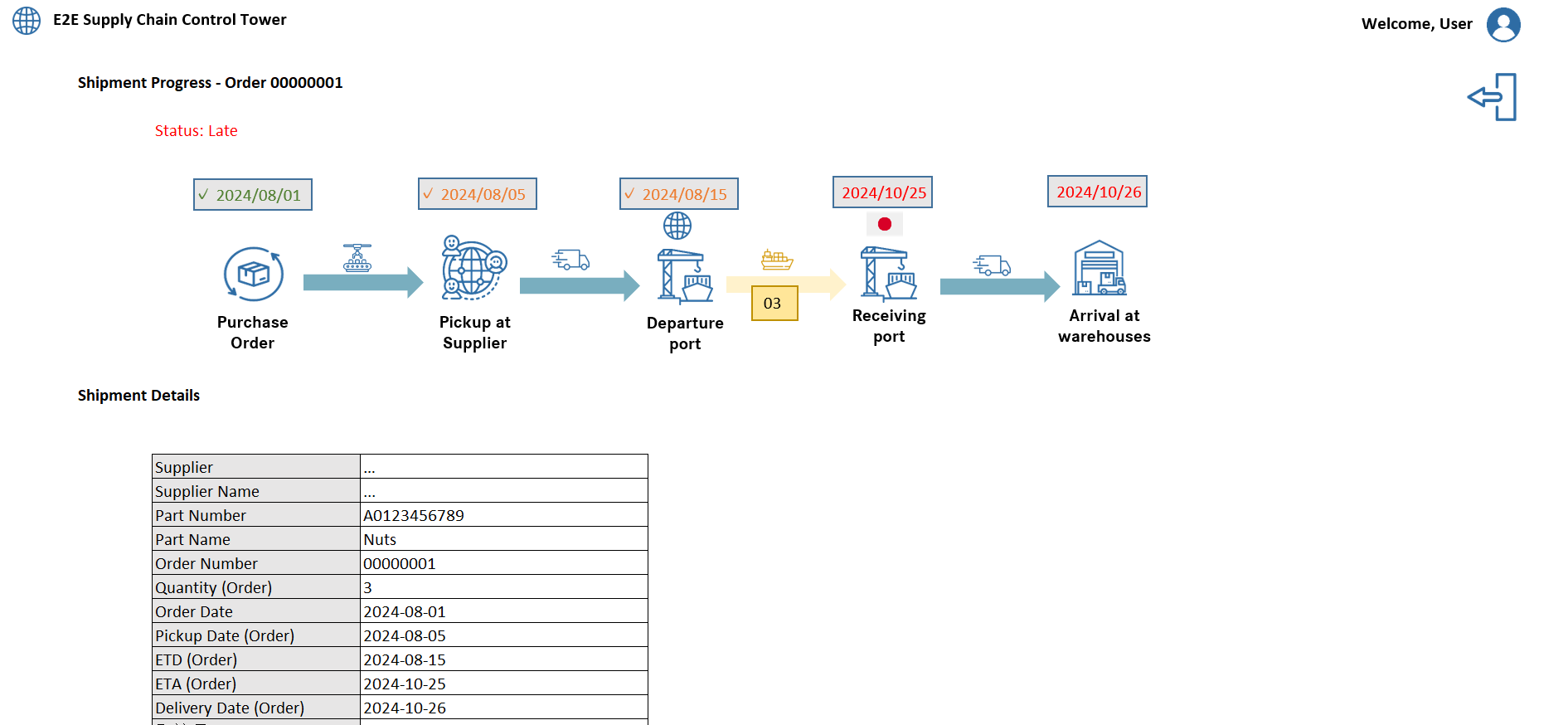

MFTBC has also enabled real-time monitoring of the transport status and estimated arrival times for imported manufacturing components arriving at Japanese ports.

Imported parts are generally shipped by vessels, but schedules can vary due to traffic, customs procedures, and weather conditions.

To streamline operations, it is crucial to accurately and promptly monitor shipping vessels and integrate that information into production plans and parts ordering. Traditionally, MFTBC operators would check vessel statuses via vessel owners’ websites or through email communications.

With the Project in place, MFTBC’s in-house system now utilizes API services*3 to centrally monitor the real-time shipping status and estimated arrival times of all vessels. This transition is expected to reduce daily workloads for operators and cut down on outsourcing costs for the company.

*3API: Application Programming Interface— a system that connects various software and applications for streamlined access from a single platform.

[Screen image of real-time monitoring of import parts transportation]

Through the Project, MFTBC will continue its digital transformation efforts throughout the entire logistics chain. The goal is to optimize the management of parts delivery and ensure a more stable vehicle production process by quickly identifying and addressing risks from external factors with improved lead times and accuracy.

SOURCE: Fuso

.

[ad_2]