[ad_1]

Innovative technology boosts the effectiveness and longevity of EV batteries.

Li-ion batteries demonstrate the highest power density when compared with alternative battery compositions. They have the capacity to store more energy in a compact, lightweight form than any other battery variant. Consequently, Lithium batteries are the preferred choice for a variety of electric vehicle models. Regrettably, lithium batteries come with certain drawbacks. They are susceptible to thermal runaway if they are damaged, under excessive loads, overcharged, or exposed to high temperatures. Thermal runaway can trigger enough heat to ignite the electrolyte, leading to a fire or battery pack explosion. Such scenarios can cause substantial harm to the battery pack, the EV, and potentially endanger the occupants.

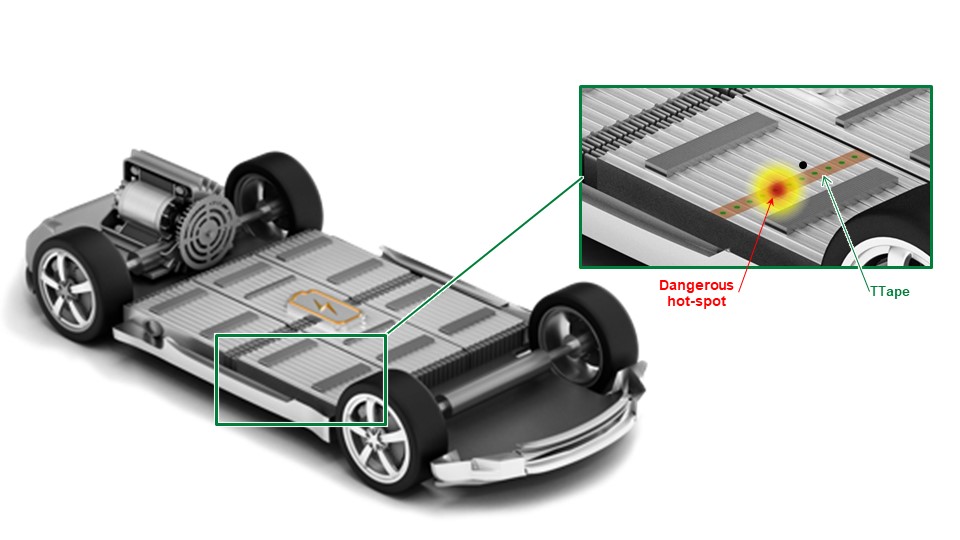

An advanced technology that manages the risk of lithium battery thermal runaway is now accessible. The latest innovation engineered by Littelfuse, the TTape™ Distributed Temperature Monitoring Device, enables prompt detection of localized battery cell overheating. This cutting-edge system aids in prolonging battery lifespan and boosting the safety of battery setups. TTape comprises a strip of tape equipped with numerous closely spaced temperature indicators. Unlike singular thermistors, TTape adheres to battery cells and flexes to match the cell shapes, allowing for comprehensive monitoring of points on a battery pack. The temperature sensors swiftly identify a cell hotspot, averting battery thermal runaway. Unlike individual thermistors limited in size that restrict the number of monitoring points and prevent close positioning, TTape resolves the obstacle of promptly detecting battery cell hotspots.

This piece introduces readers to the advantages of the TTape Distributed Temperature Monitoring Device and elaborates on its features. Additionally, a schematic diagram demonstrates its application in a protection scheme. Designers will appreciate TTape as a streamlined component for ensuring optimal longevity and safe operation of lithium-ion batteries.

Overview of TTape

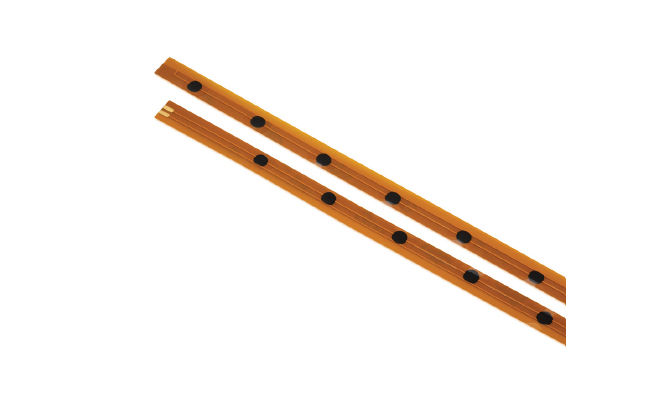

TTape is a flexible, slim strip containing printed temperature indicators positioned closely for efficient spatially precise temperature monitoring. With a thickness below 500 µm, it can adapt to the shape of any battery pack. Figure 1 displays the TTape strip with the printed temperature indicators (PTIs).

The printed temperature indicators are miniature dots consisting of polymer positive temperature coefficient material. These indicators are linked in series. When a temperature surpasses the threshold level, the resistance of an indicator increases by more than 1000 times.

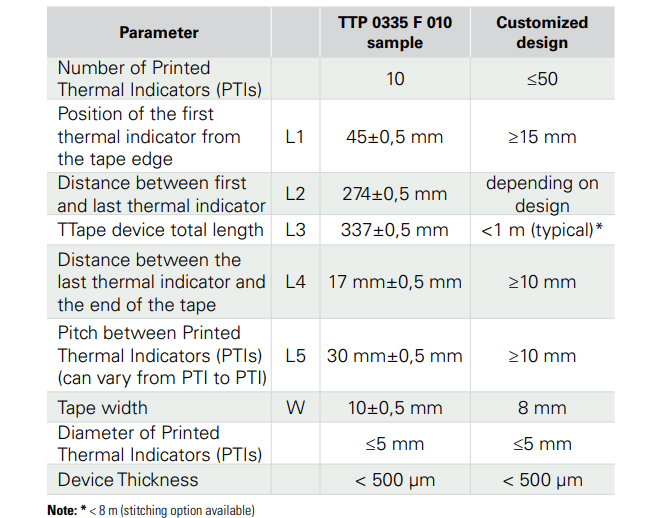

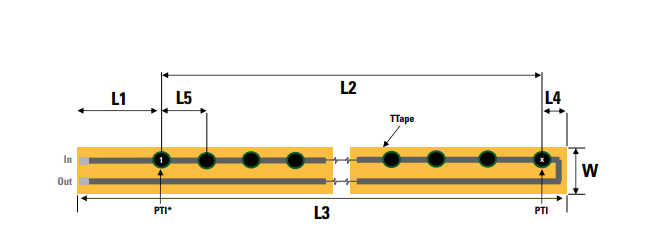

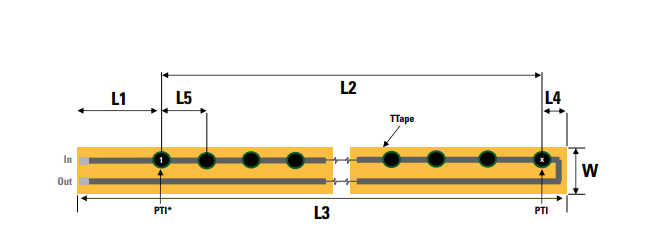

Figure 2 outlines the dimensional specifics of the TTape Distributed Temperature Monitoring Device. Temperature sensors can be positioned approximately 10 mm apart. TTape is offered with a narrow width of either 8 mm or 10 mm and a standard length of 337 mm. Tailored variants can reach up to 1 m in length. Pressure-sensitive adhesives affix the TTape to diverse surfaces like metal, polyamide, PET, and polyimide.

A standard TTape length of 337 mm contains ten printed thermal indicators. Custom models can incorporate up to 50 of these indicators. The printed thermal indicators possess a maximum diameter of 5 mm with a standard spacing of 30 mm. The close proximity between indicators enhances spatial resolution for monitoring all cells on a battery pack. Conventional temperature sensors cannot achieve such meticulous monitoring of individual battery cells. Furthermore, owing to its sub-500 µm thickness, TTape can conform to the irregular surfaces of a battery pack and establish direct contact with individual cell points.

The TTape connects with an electronic circuit via a 2-wire solder pad interface. Figures 1 and 2 feature the two solder pads, and Figure 2 delineates their functions.

The thermal tape has a temperature threshold of 58 ± 3° C to detect early overheating before a battery cell reaches a critical temperature. Various battery chemistries can operate under 60° C before standard safety circuits engage. When the temperature exceeds 60° C, the battery management system halts charging or discharging. The 58° C threshold accommodates temperature fluctuations during the battery’s operation. The thermal indicators respond in less than one second. If the battery’s temperature remains above 58° C for more than a second, the TTape monitor triggers an alert.

To prevent rapid switching near the temperature threshold, the TTape material is designed with hysteresis to protect components and prevent false alarms. This ensures that the system responds only to actual overheating scenarios, enhancing the safety and longevity of the battery pack.

Designing the Circuit

The TTape can integrate with TTL-level circuits at 5 V or 3.3 V. The circuit diagram in Figure 3 outlines the configuration for the TTape monitor. VT goes high when the thermal indicators sense a temperature above 58° C, and switches to a high resistance. VT goes low when the temperature is below 58° C or has dropped below 42° C after exceeding the threshold. Once surpassing the threshold, the indicators exhibit a hysteresis of around 16° C. The hysteresis curve of the TTape device is shown on the right side of Figure 3.

The logic circuit is straightforward, using an ideal value of 200 KΩ for RP. VT can provide feedback to an A/D converter in a microcontroller. Under normal conditions, the 5 V circuit consumes only 25 µA, equating to 125 µW. The TTape requires only one A/D input for the microcontroller to monitor battery cell temperatures, making integration into battery management systems or interfaces straightforward.

Comparing with Traditional Sensors

With sensors situated close to the battery cells and a slim form factor that conforms to any surface, the TTape can detect temperature changes quicker than traditional sensors, as illustrated in Figure 4. A thermistor placed one cell away from an overheating cell can take over two minutes to react to elevated temperatures, whereas the TTape with sensors on each cell responds in under a second.

Unlike NTC sensors, TTape doesn’t require calibration as it functions as a binary device. Additionally, the electronic processing for TTape sensors doesn’t need a temperature conversion table, simplifying integration and enhancing efficiency.

Being a compliant tape, the TTape occupies minimal space on the battery pack. It facilitates simple installation and enables monitoring of any battery pack configuration. The installation example of a TTape monitoring strip on a battery pack can be seen in Figure 5.

Advanced monitoring for increased safety

The TTape Temperature Monitoring Platform offers designers the exceptional capability to have highly dense temperature monitoring on every cell group within an EV battery. This high-density monitoring helps in the prevention of premature aging by identifying and mitigating temperature hotspots on individual or groups of cells. This cost-effective, space-efficient solution enhances safety and prolongs battery cell lifespan. Additionally, the TTape monitoring device is certified AEC-Q200 for usage in automotive vehicles.

For more details on the TTape Distributed Temperature Monitoring Platform, including installation instructions and circuit implementation, refer to the TTape™ Distributed Temperature Monitoring Device Application Note.

To receive technical support, please visit the TTape product page and reach out to Littelfuse at www.littelfuse.com.

[ad_2]